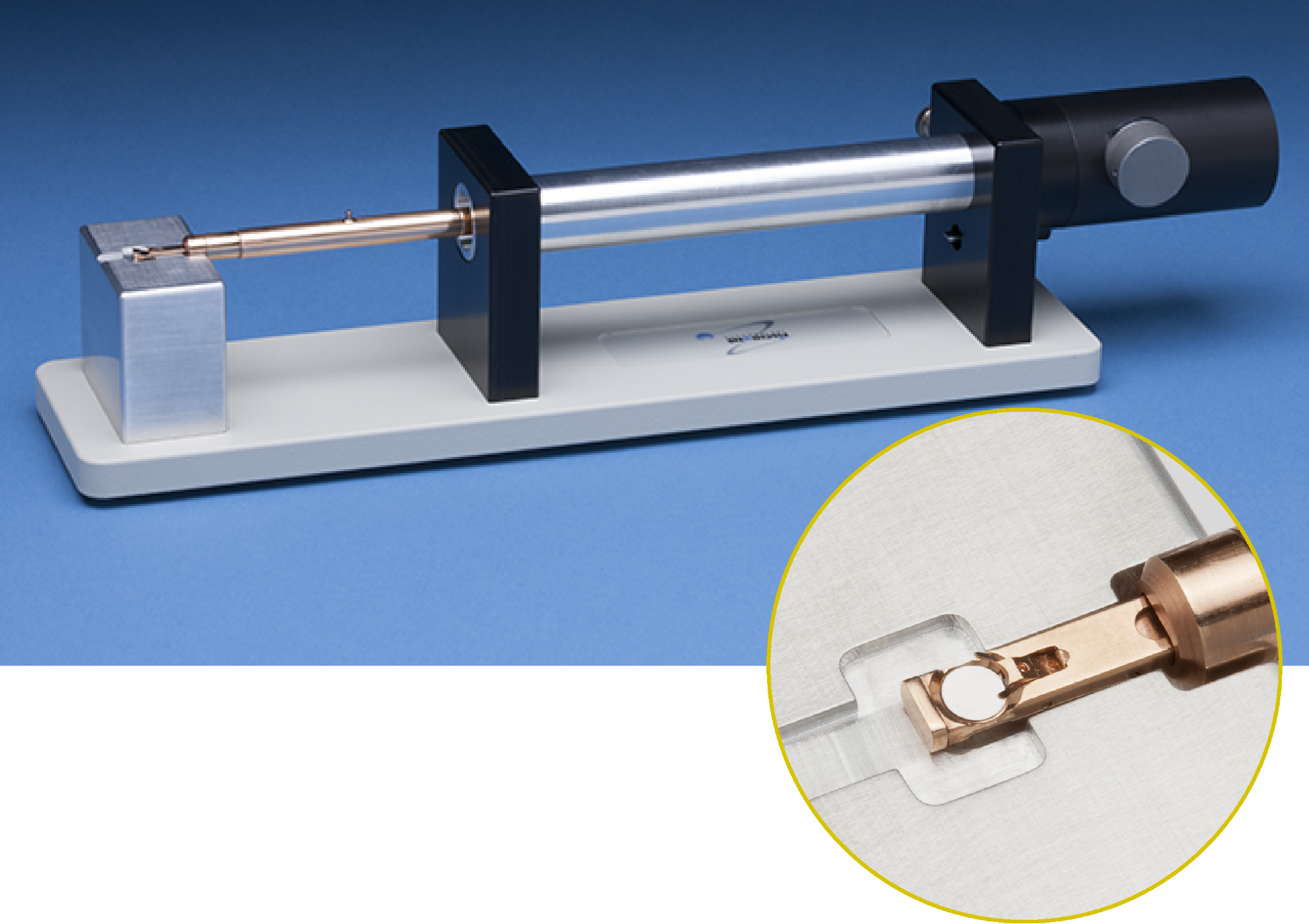

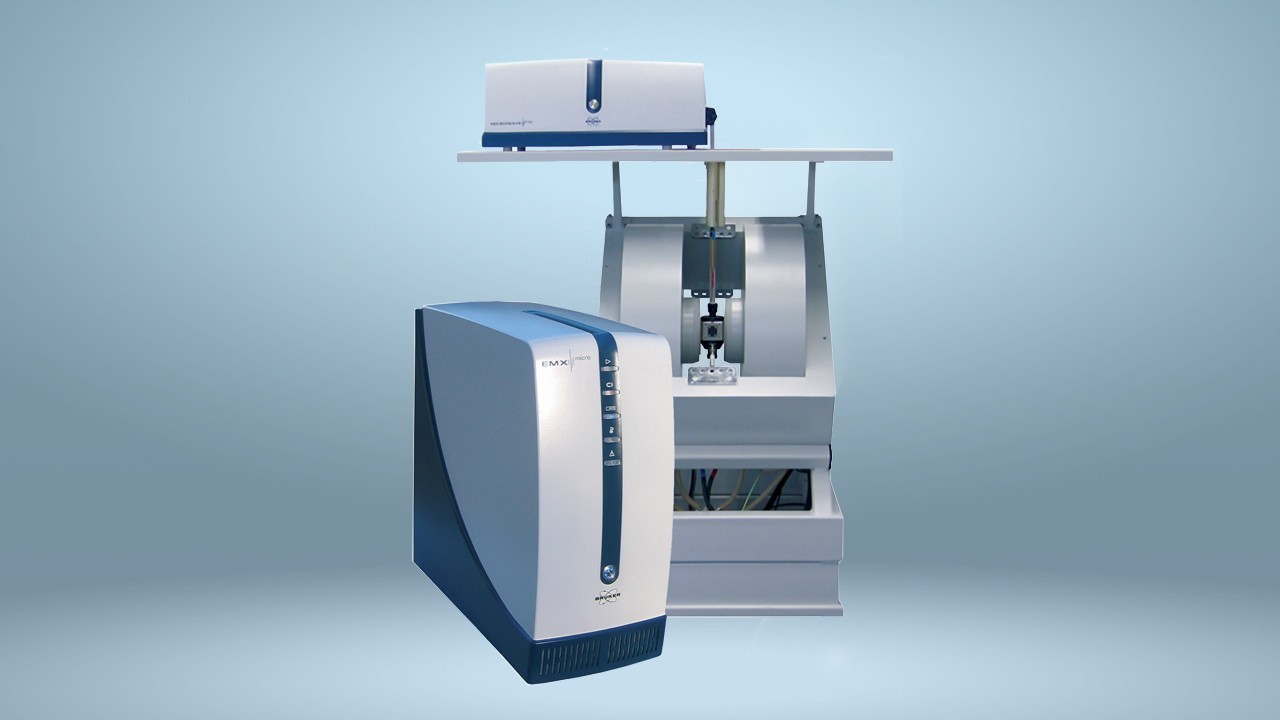

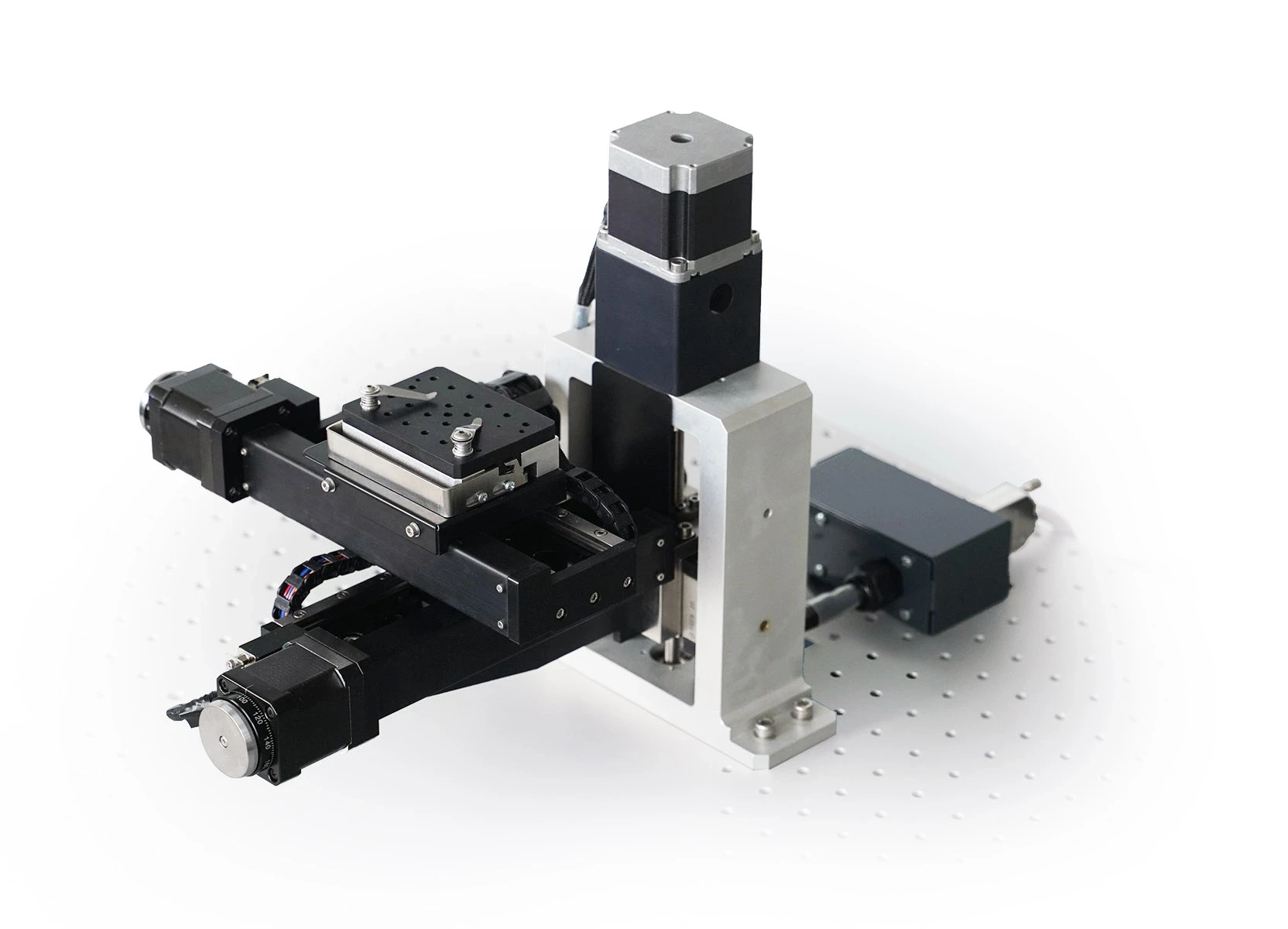

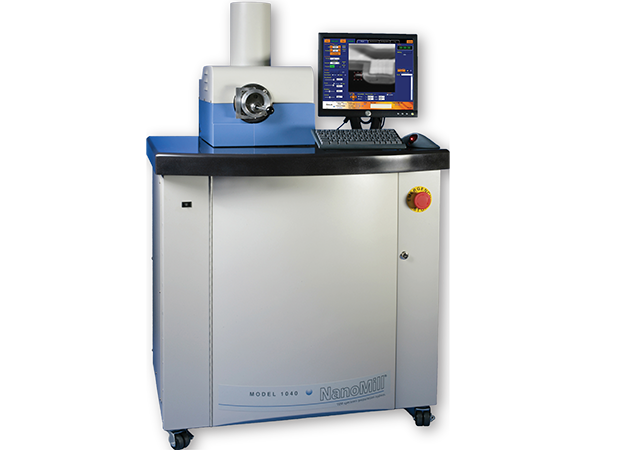

A state-of-the-art ion milling and polishing system offering reliable, high performance specimen preparation. It is compact, precise, and consistently produces high-quality transmission electron microscopy specimens with large electron transparent areas from a wide variety of materials..png)

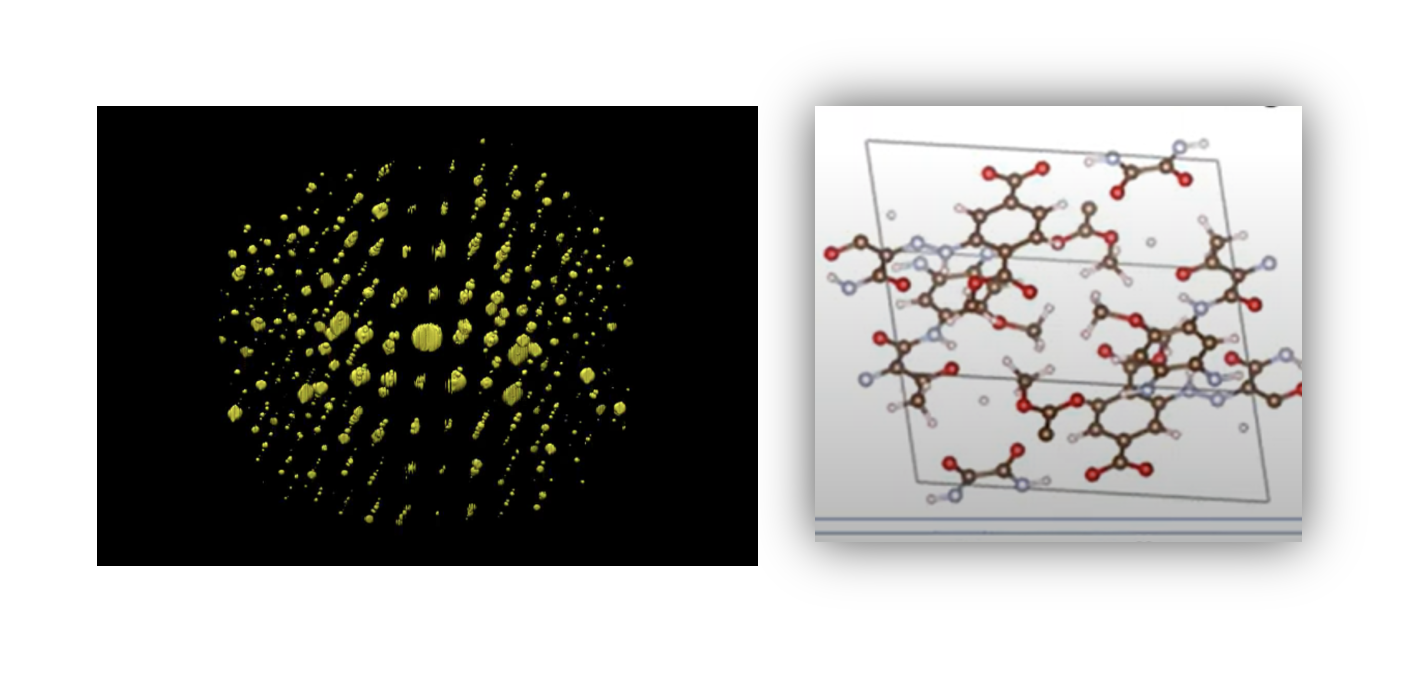

For many of today’s advanced materials, analysis by TEM is the best technique for studying material structure and properties. The TEM Mill is an excellent tool for creating the thin, electron transparent specimens needed for TEM imaging and analysis. Ion milling with low angles of incidence, combined with low-energy ion source operation, minimizes irradiation damage and specimen heating.

Because it facilitates the uniform thinning of dissimilar materials, low-angle milling is highly beneficial when preparing layered or composite materials, as well as cross-sectional TEM (XTEM) specimens.

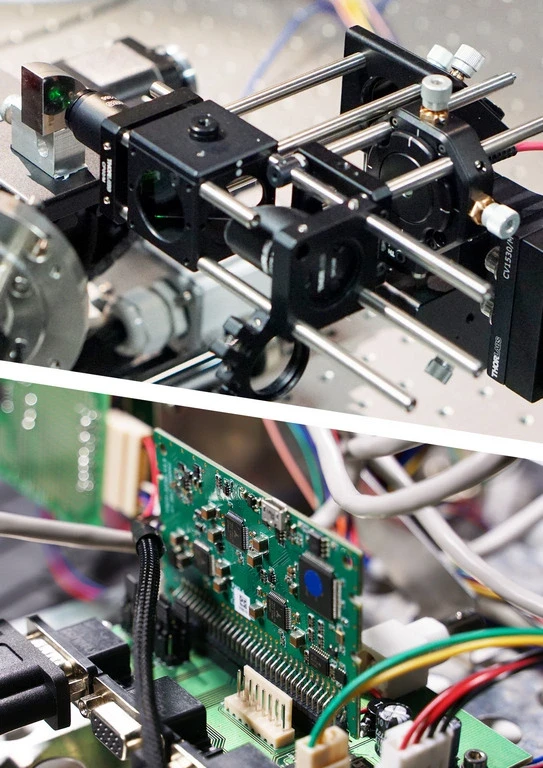

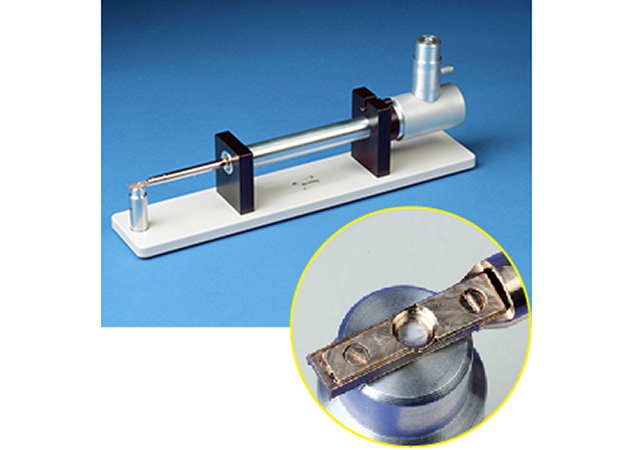

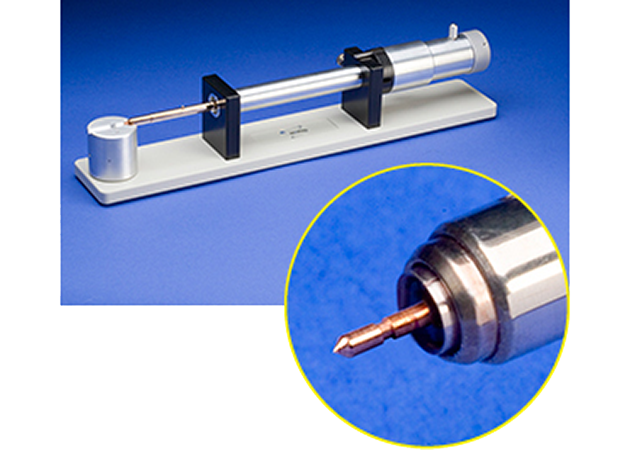

- Two independently adjustable TrueFocus ion sources

- High energy operation for rapid milling; low energy operation for specimen polishing

- Ion source maintains its small beam diameter over a wide range of operating energies (100 eV to 10 keV)

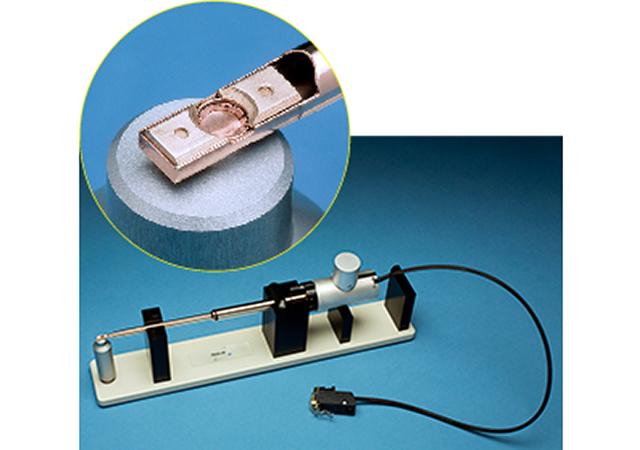

- Liquid nitrogen-cooled specimen stage (optional)

- Faraday cups for the direct measurement of beam current from each ion source

- Independent ion source gas control

- Adjustable milling angle range of −15 to +10°

- In situ viewing and image capture during milling

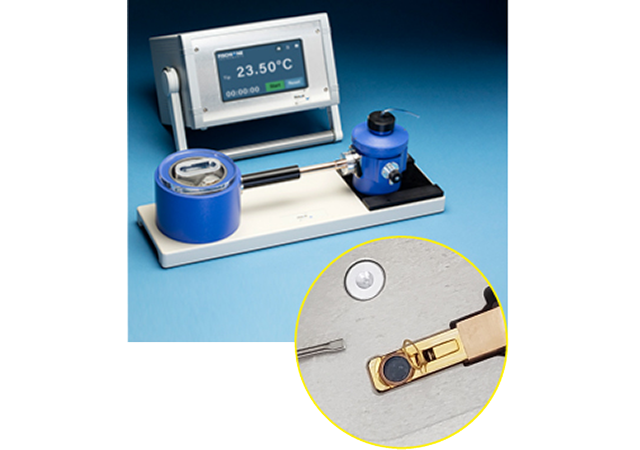

- Automatic termination by time, temperature, or laser photodetector (optional)

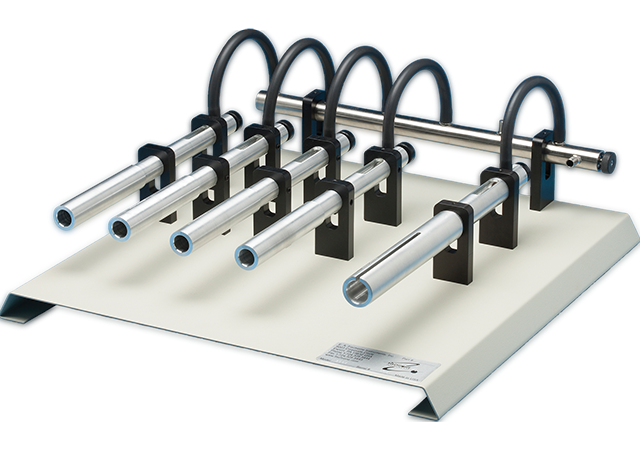

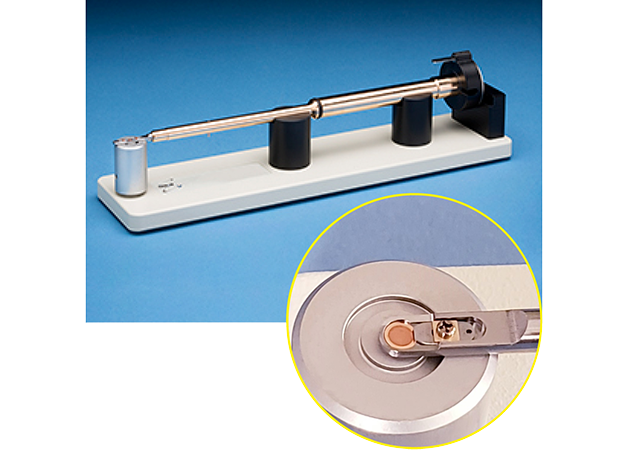

- Specimen holder and loading station with X-Y adjustment (optional)

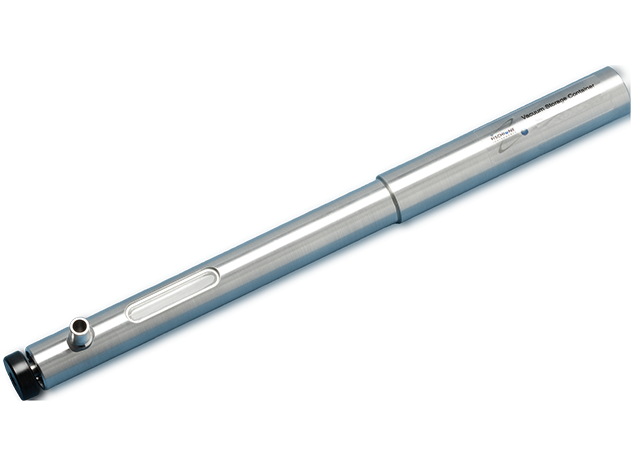

- Vacuum or inert gas transfer capsule (optional)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-