Technology

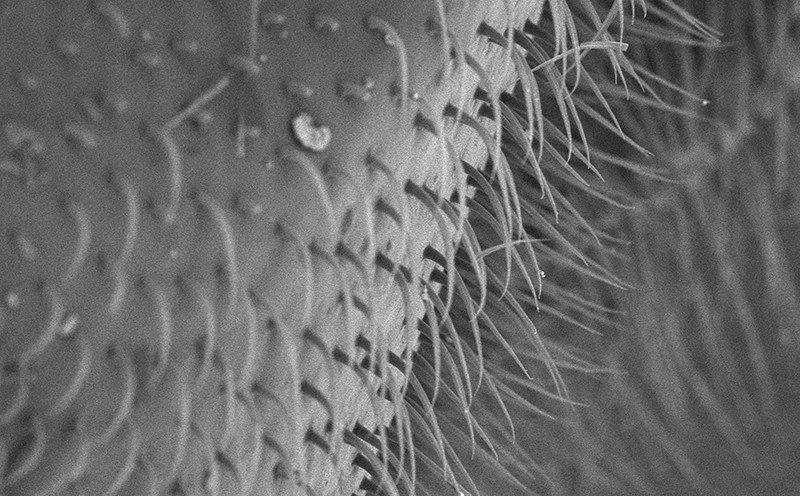

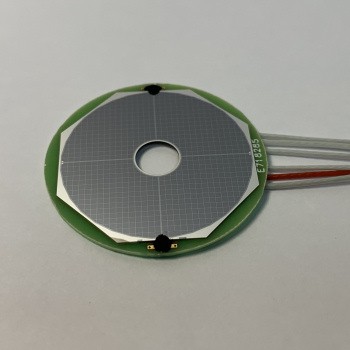

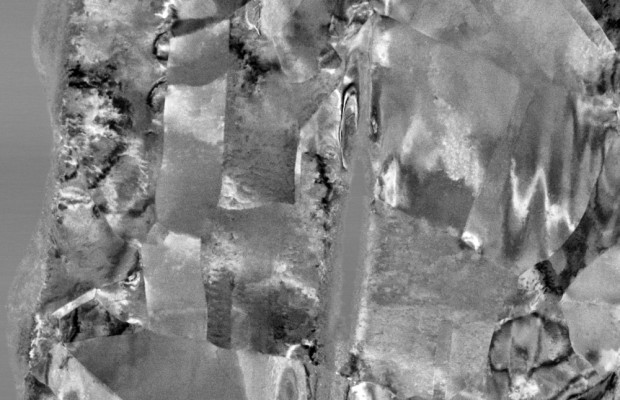

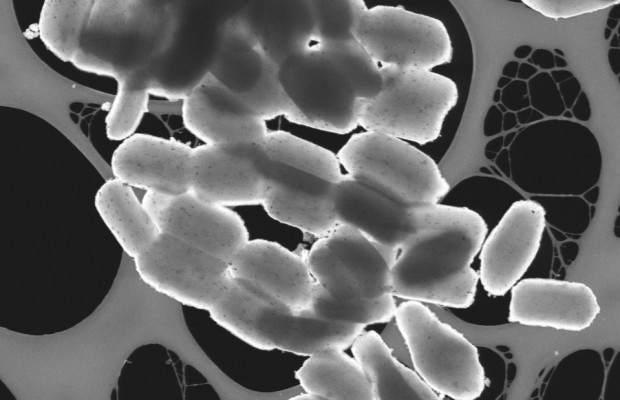

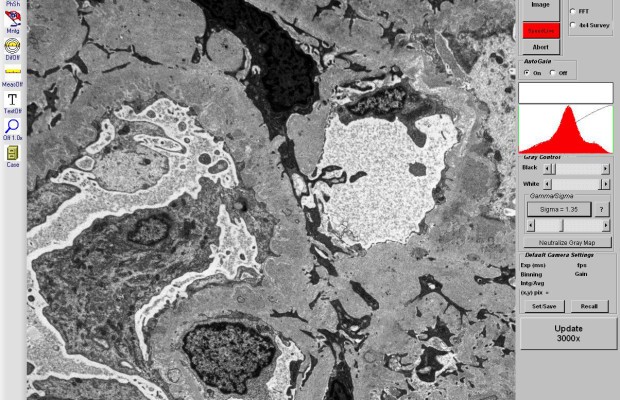

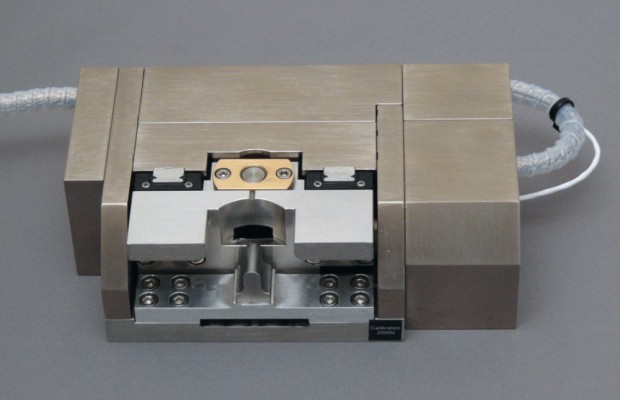

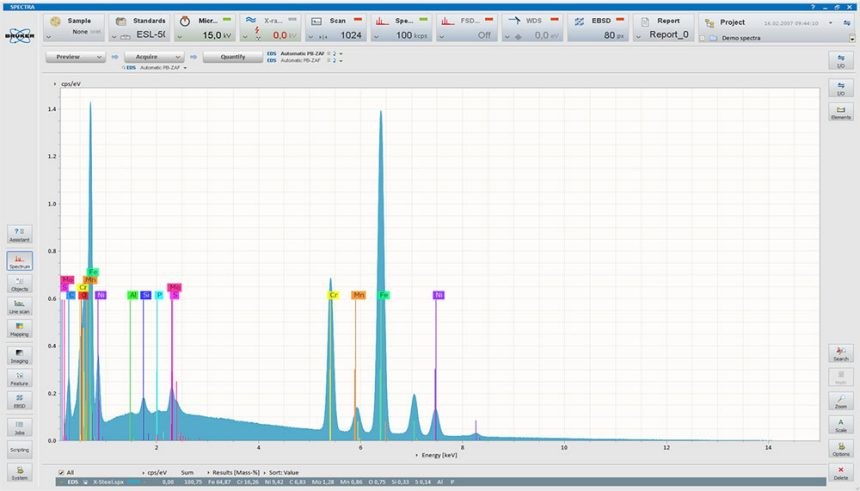

The LUXORAu is typically used for SEM imaging applications up to 100000x magnification where sample charging might be an issue, as the coating strongly reduces sample charging by increasing conduction.

The coater is designed to improve secondary electron emission. As a result, the microscope’s detectors will pick up more hi-res imaging details.

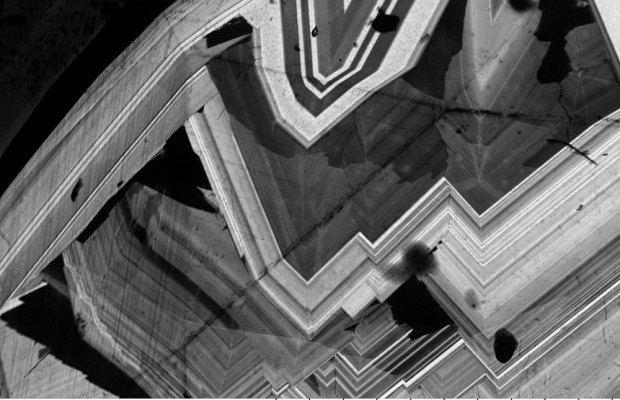

Another advantage is the reduced beam penetration, which significantly improves edge resolution. Furthermore, this prevents sensitive samples from being damaged.

Benefits

* OPTIMISED USER INTERFACE

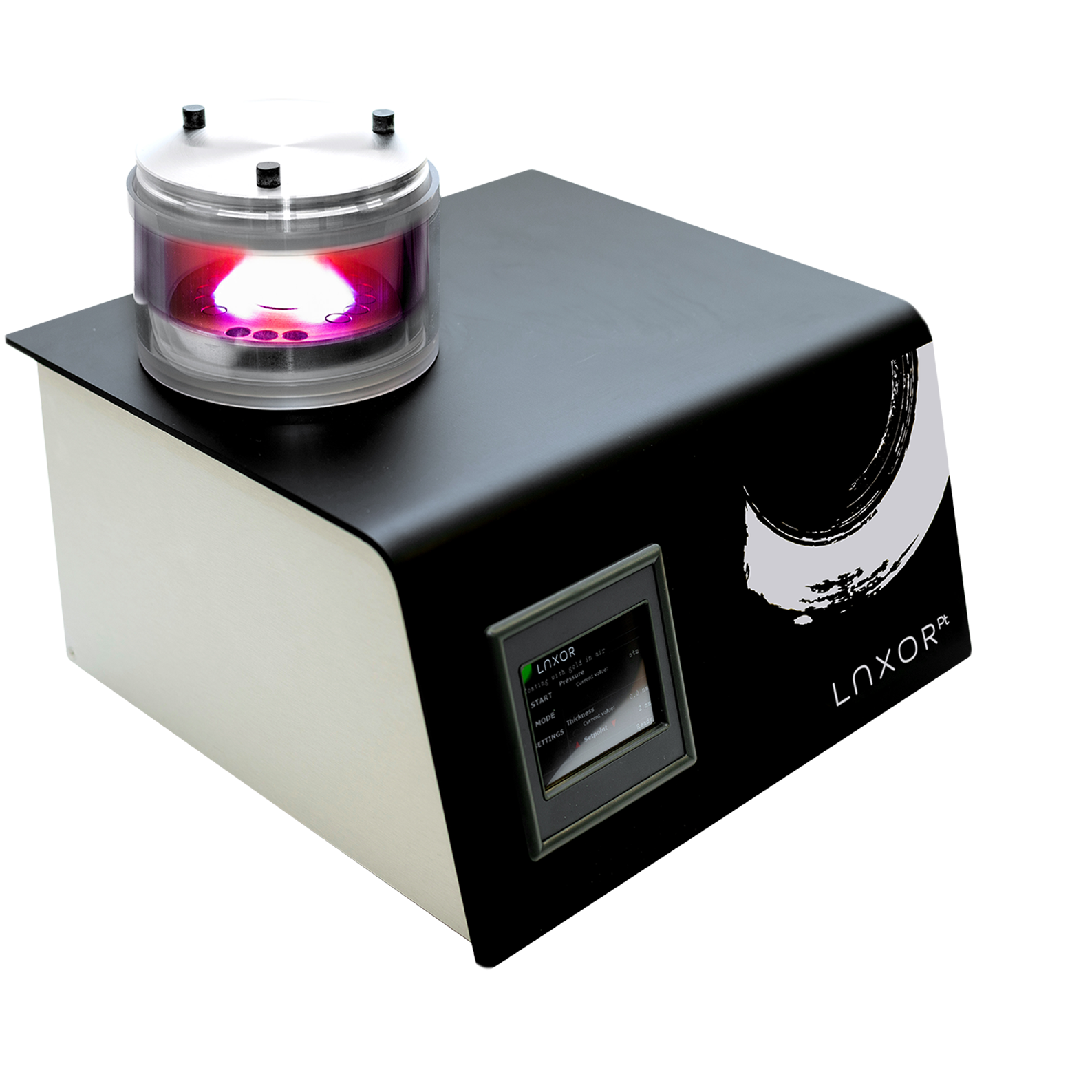

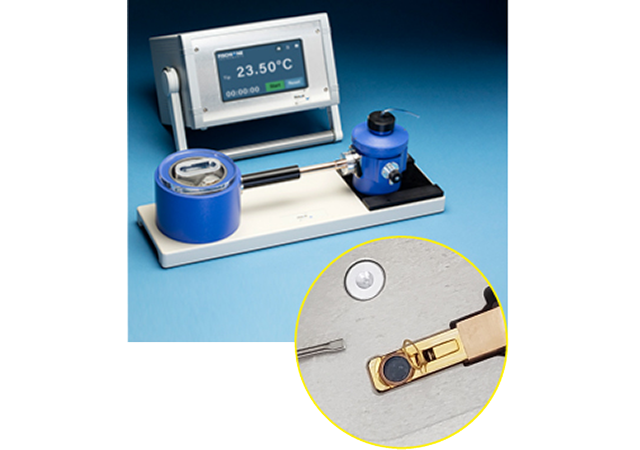

First of all, the LUXORAu is remarkably easy to use. Using the built-in touchscreen, the coating process can be initiated with just a few clicks.

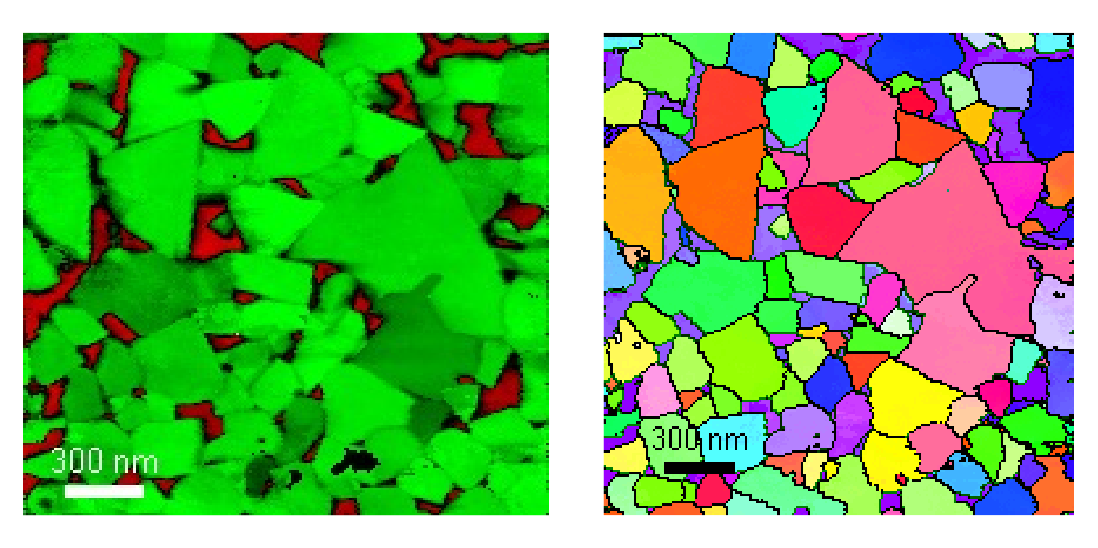

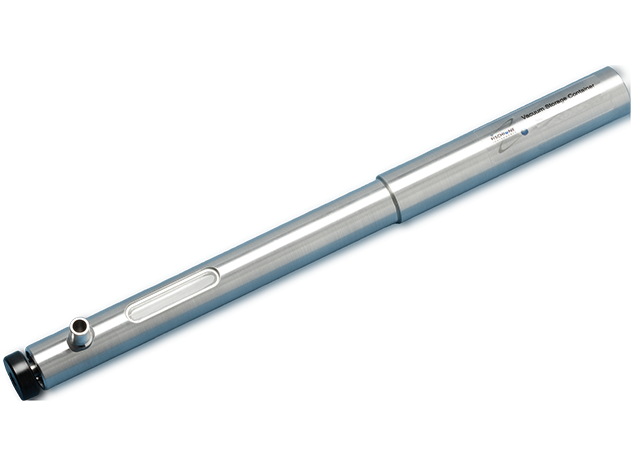

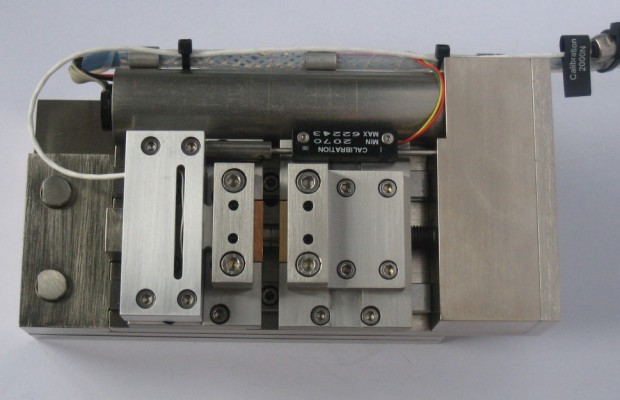

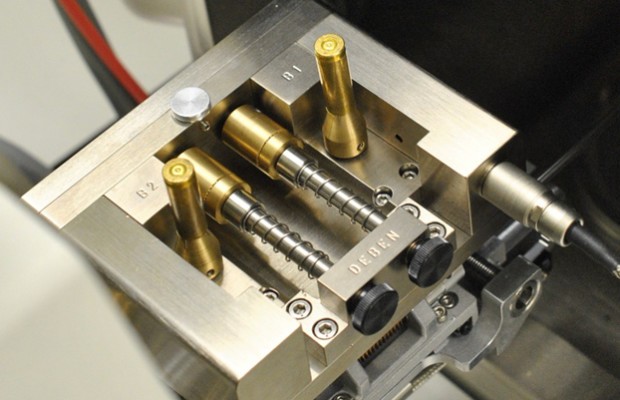

* SUPERIOR GOLD COATING RESOLUTION

Field tests clearly show that the LUXORAu generates more homogeneous and smaller gold grains, compared to other coating instruments in the market. Furthermore, the A² technology ensures identical, reproducible coating results, day after day and year after year.

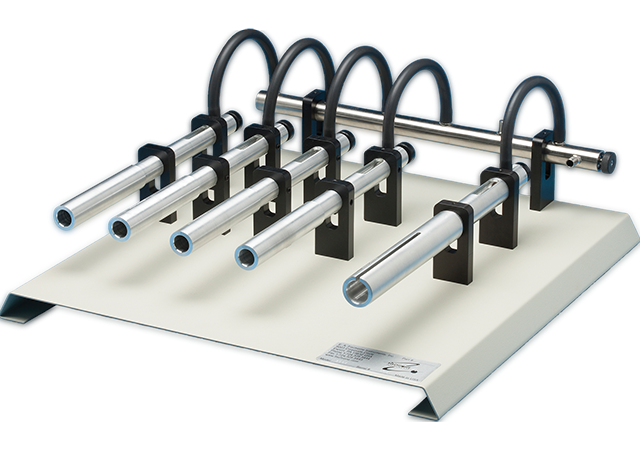

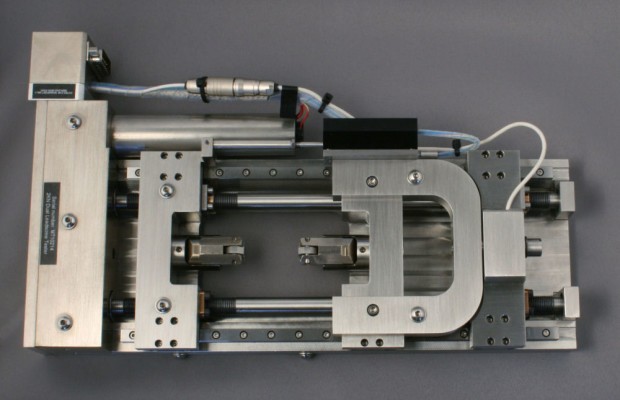

* INCREASED SPEED & EFFICIENCY

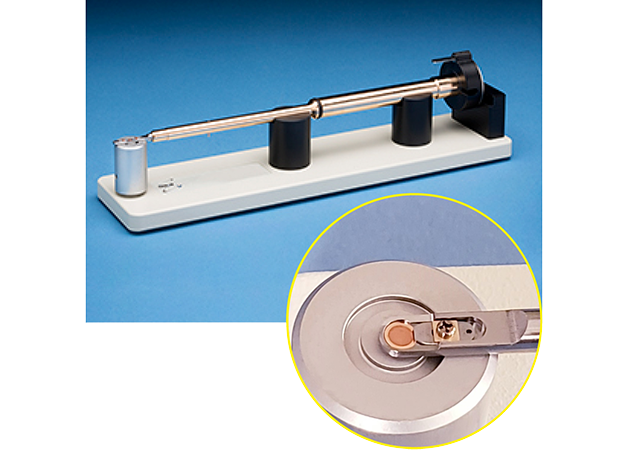

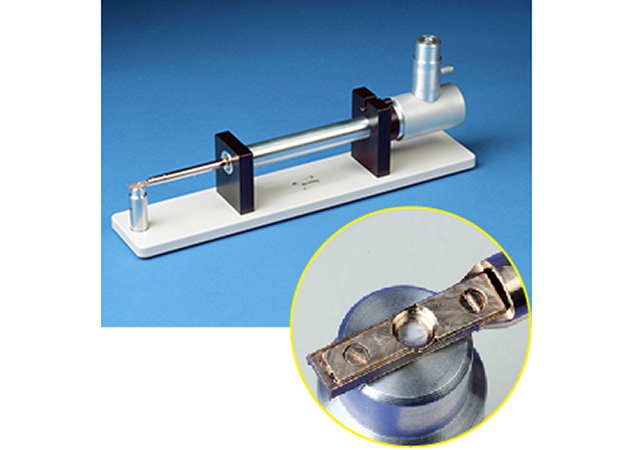

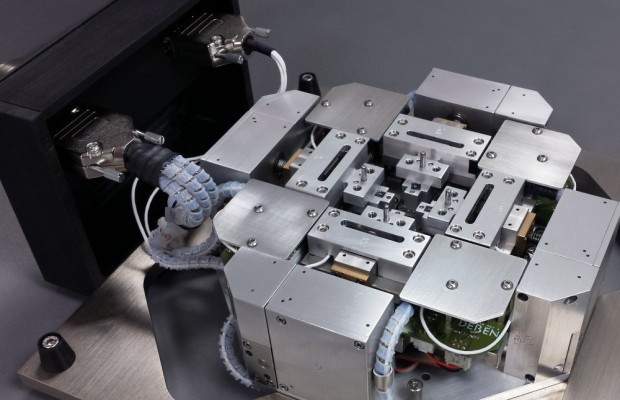

The LUXORAu is able to process up to six samples in one go. And while the gold coating procedure is very precise, it is also remarkably fast.

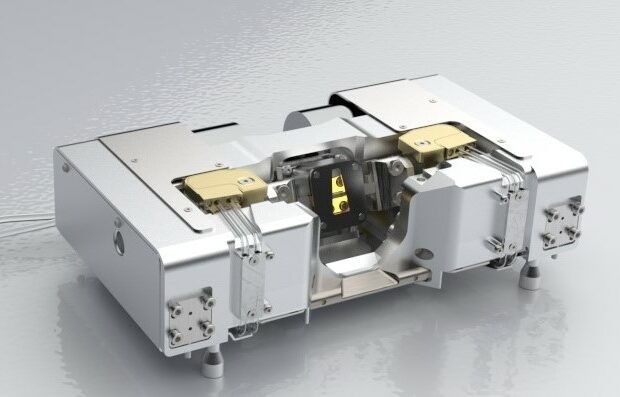

* ADVANCED SEM PROTECTION

The unique ‘upside down’ design of the LUXORAu makes sure that loose particles will be removed during the coating process. This way, your SEM is optimally protected.

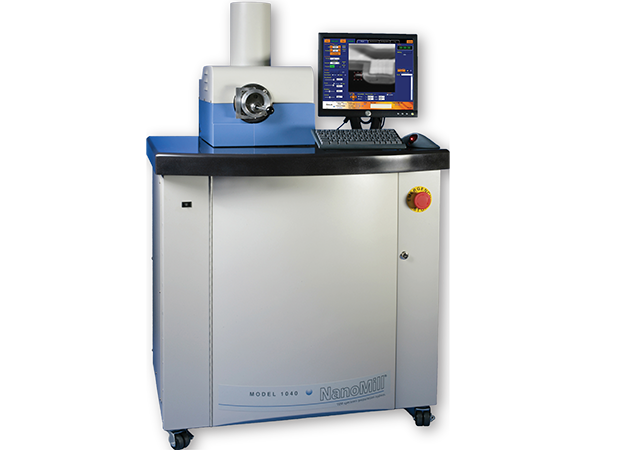

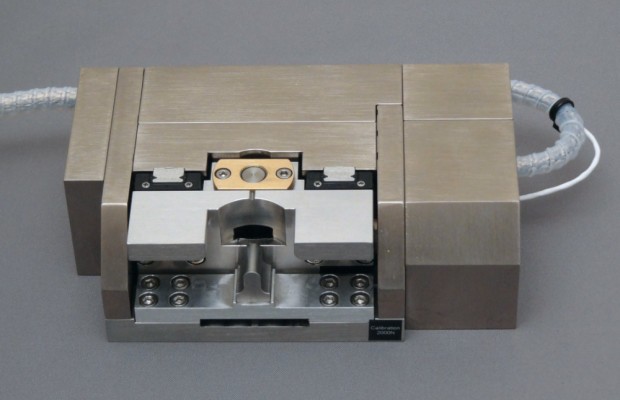

* ROBUST DESIGN, MADE IN GERMANY

Despite its modest footprint and elegant appearance, the LUXORAu is a robust, sturdy device. It is designed to be used intensively and run hassle-free for many years.