The addition of Spin Finish to fibers is an important part of improving their downstream handling during the manufacturing process. Typically, a Spin Finish preparation is a water-based emulsion consisting of emulsifiers, lubricants, and anti-static agents. Regardless of its composition, all types of Spin Finish share common characteristics, including acting as lubricants in the manufacturing and processing of filaments, yarn, and industrial fibers.

Features

The Role of Spin Finish

Natural wax or grease or two inherent lubricating compounds found in natural fibers. These compounds are necessary for textile processing. More often than not, however, industrial fibers lack sufficient moisture content and feature high frictional coefficient. The application of a Spin Finish ultimately corrects the coefficient of friction and virtually eliminates any static electrical charge.

In turn, the Spin Finish imparts “sliding” characteristics to the fibers and offers adequate thread joining properties. During the spinning process, finished filaments are coiled into cans, which are then grouped together and “fed” into the drawing stage. During this stage, the filaments will often pass through guiding and drawing elements. This can only be accomplished if the filaments are able to slide easily over the elements while preventing slippage.

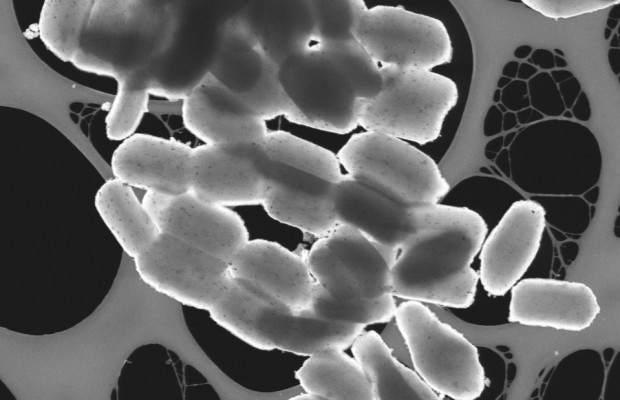

Spin Finish on a fiber surface, while only a few molecules thick, is a crucial component that can either make or break the performance of processing. Properly distributed Spin Finish in fibers allow the fibers to run more smoothly through spinning machines and ensure rapid and more reliable operation. Additionally, a Spin Finish helps operators avoid the problem of static electricity, improves cohesion of filaments, and guarantees an adequate amount of lubrication to the fibers to support proper handling. In addition, Spin Finish is required for artificial fibers for the conversion into textile materials.

Applicable materials for Spin Finish include:

- Technical textile and high-performance fibers

- Staple fibers

- Non-woven fabrics

- Texturized samples

- Polyester, polyamide, polypropylene, polyethylene, polyacrylonitrile fibers

- Yarns

But determining the appropriate levels of Spin Finish is not always easy. Determining Spin Finish levels needs to be accomplished quickly and continuously, warranting the need for improved methods of assessment.

Benefits

- Set of Bruker Calibration Transfer and Validation Samples provided

- Very few calibration samples necessary (3 – 5)

- Independent from sample color, surface or yarn count

- No solvent required

- More reproducible than wet chemistry

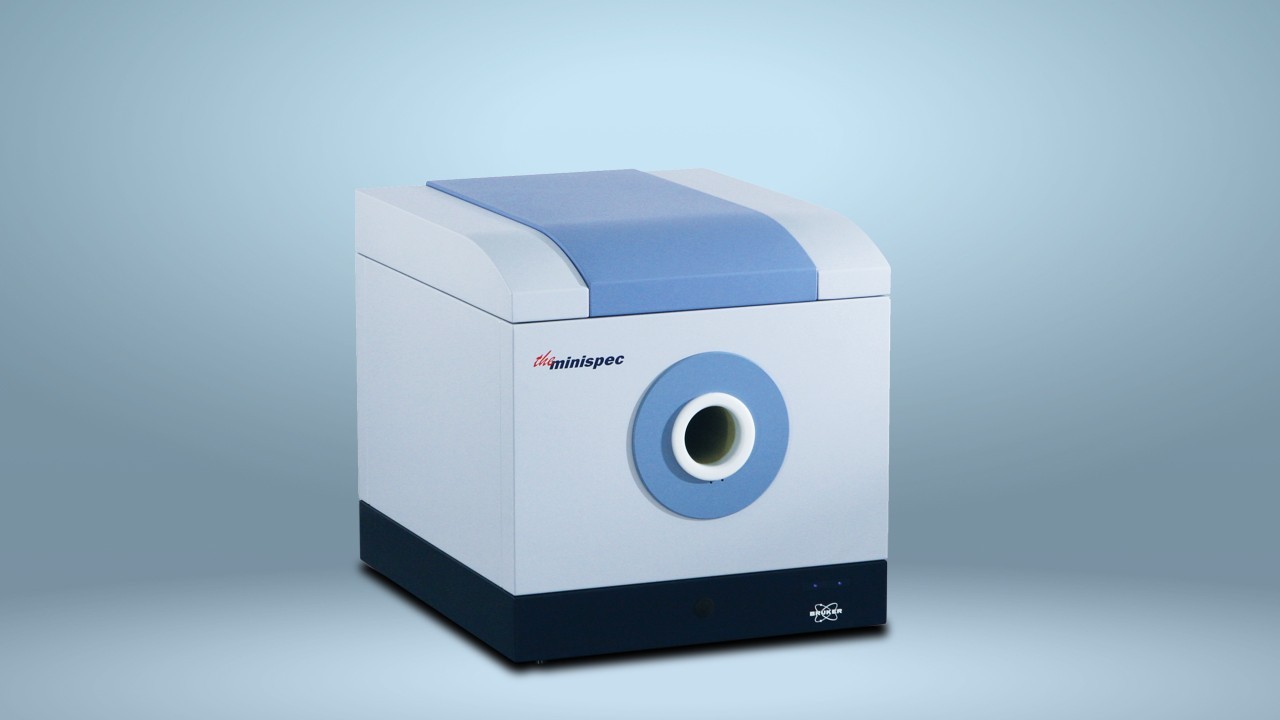

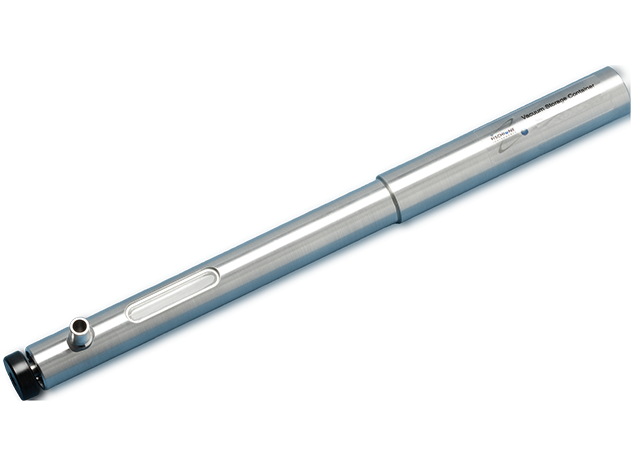

In certain applications, such as in the production of bulletproof vests, textiles must be free of Spin Fish. Other applications necessitate complete clearance of Spin Finish from the final product, such as windproof or water repellent surfaces. The mqOne can help detect Spin Finish at very low concentrations, helping in the production of these products that require very little to no Spin Finish.

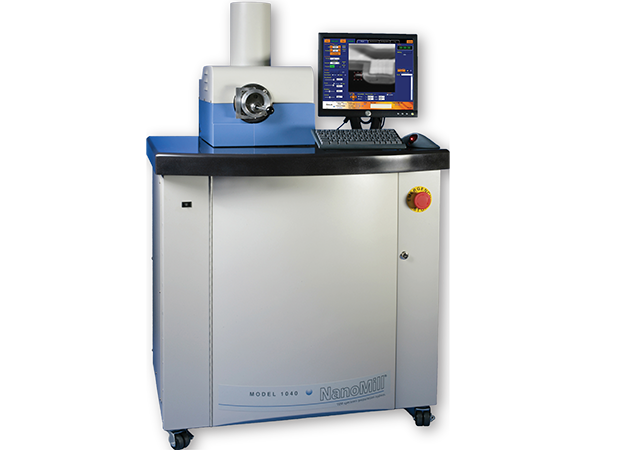

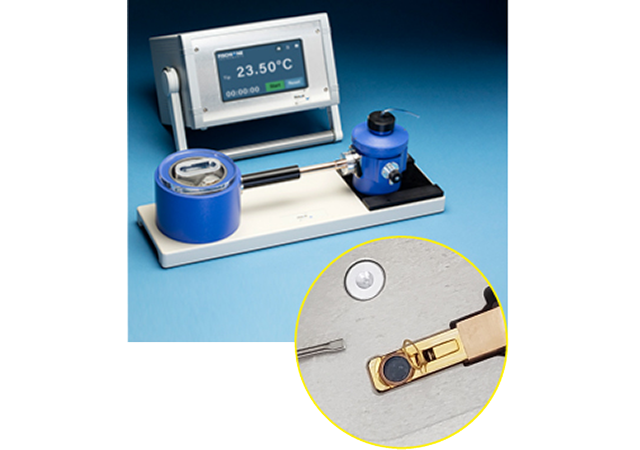

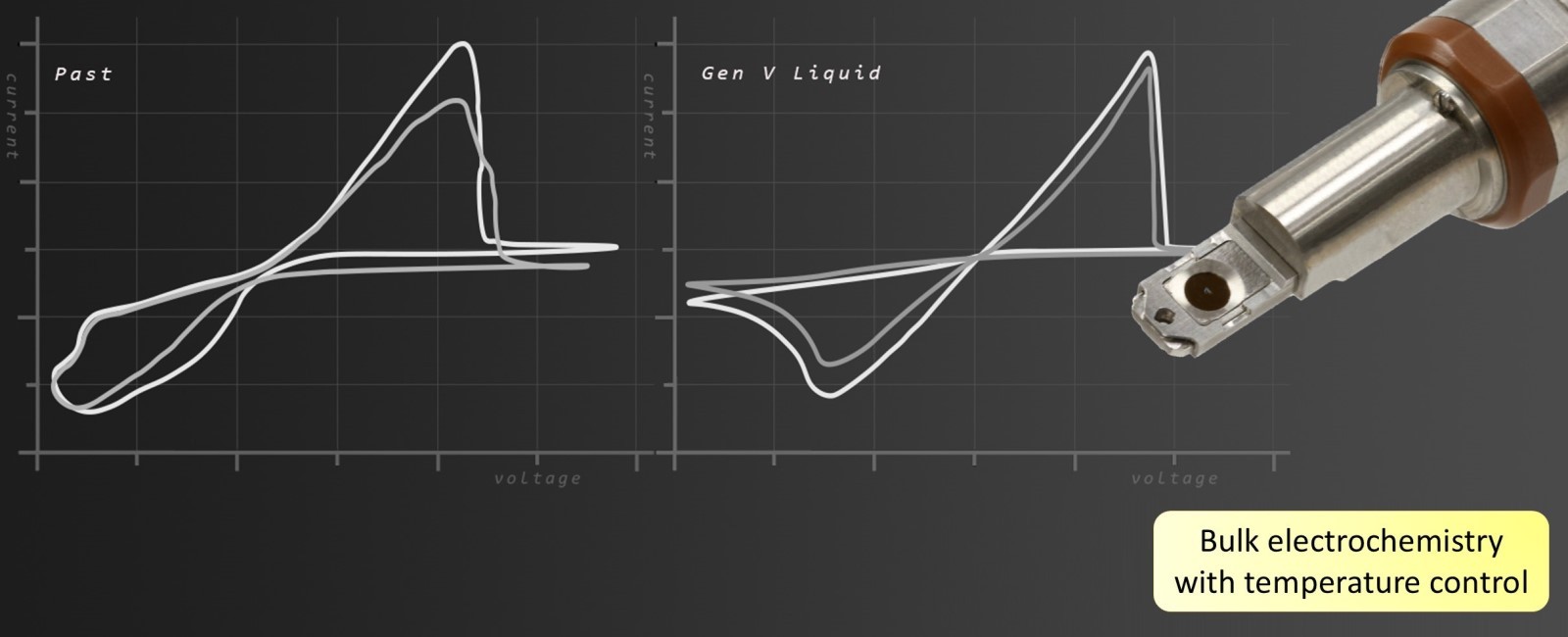

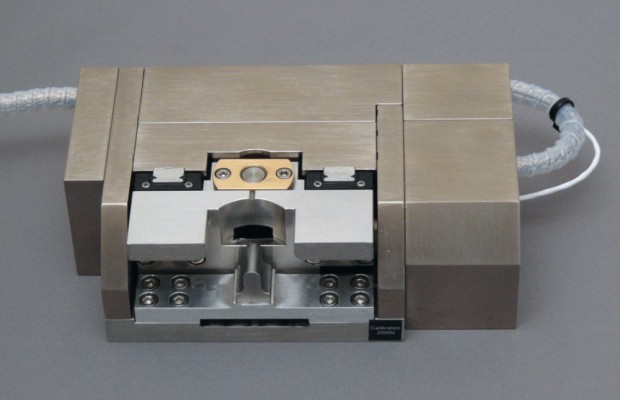

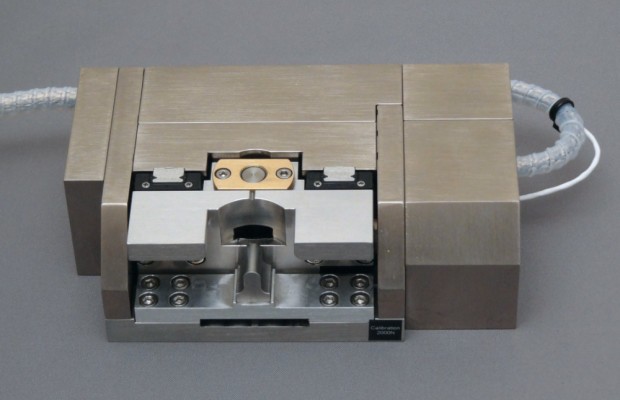

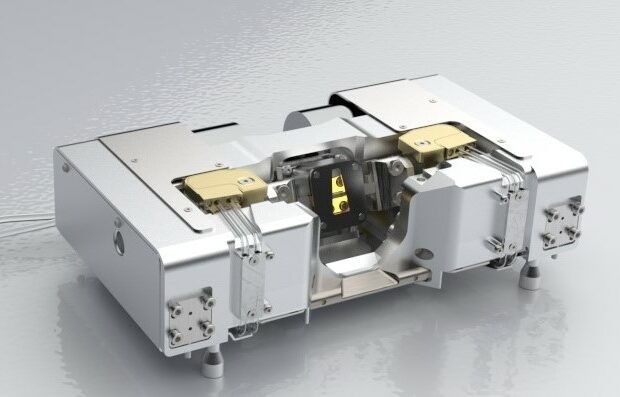

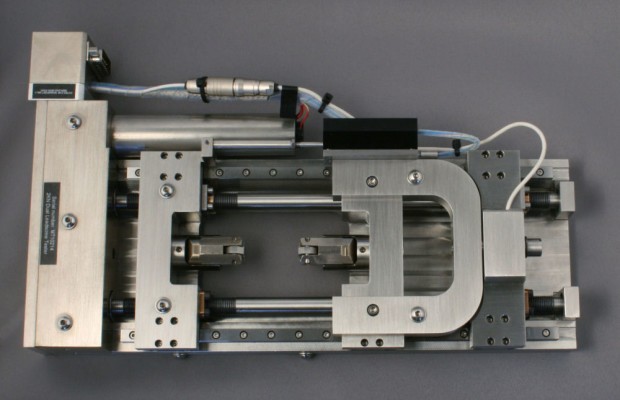

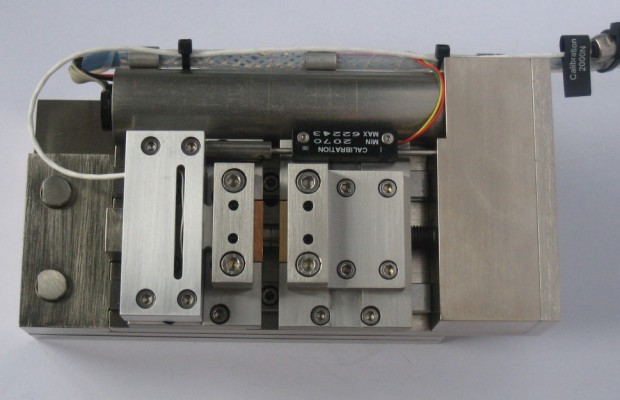

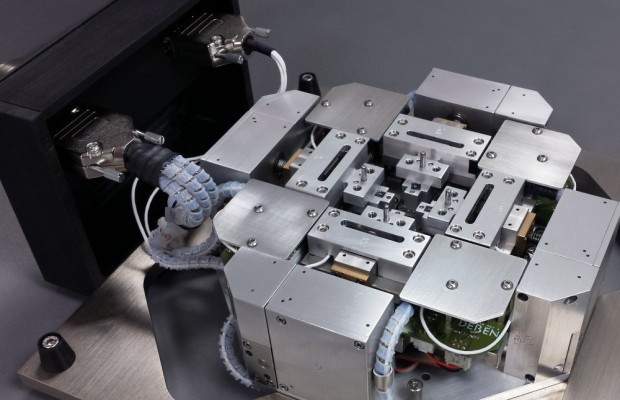

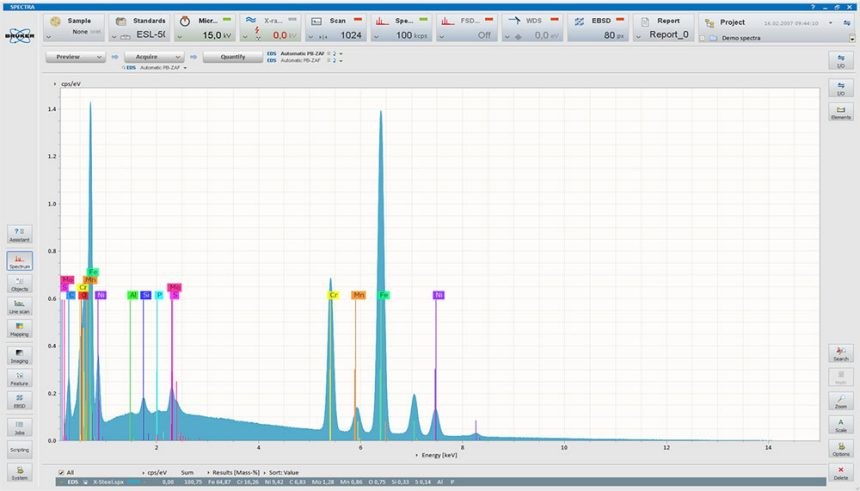

The one-unit design of the mqOne system ensures the operator will receive reliable results each time, both in terms of long- and short-term stabilities. The system is also 2 to 3 times more accurate than classical wet chemical analytical methods. In addition, the mqOne analyzer features a Daily Check sample, providing the operator ease of mind in knowing that the system’s performance is checked and guaranteed each day. For this solution, Bruker offers a service contract and full application support.

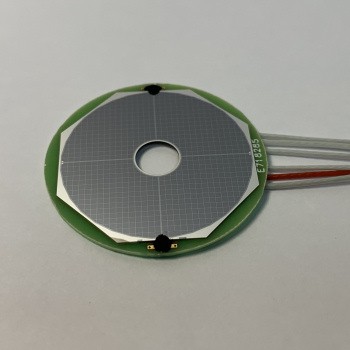

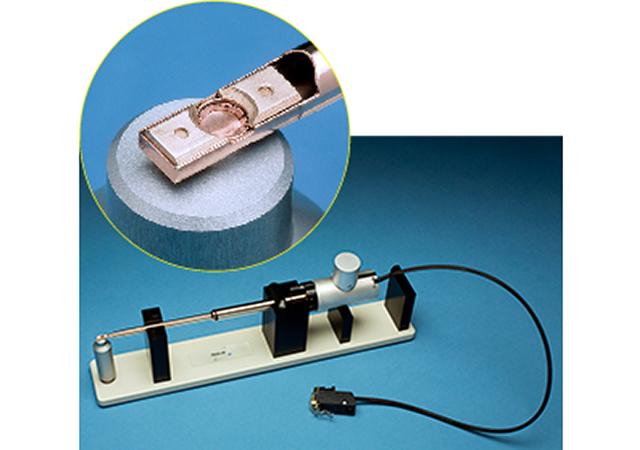

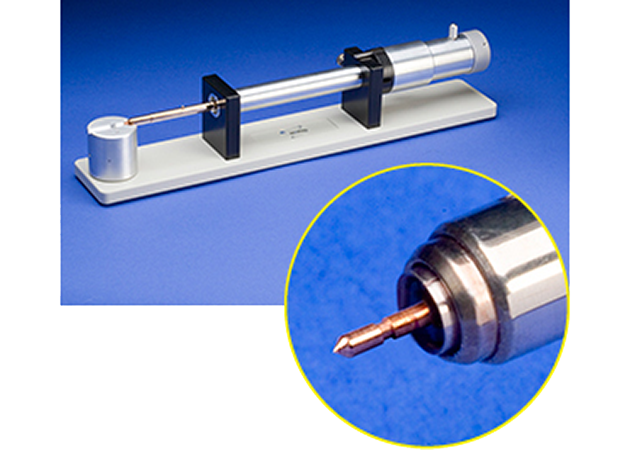

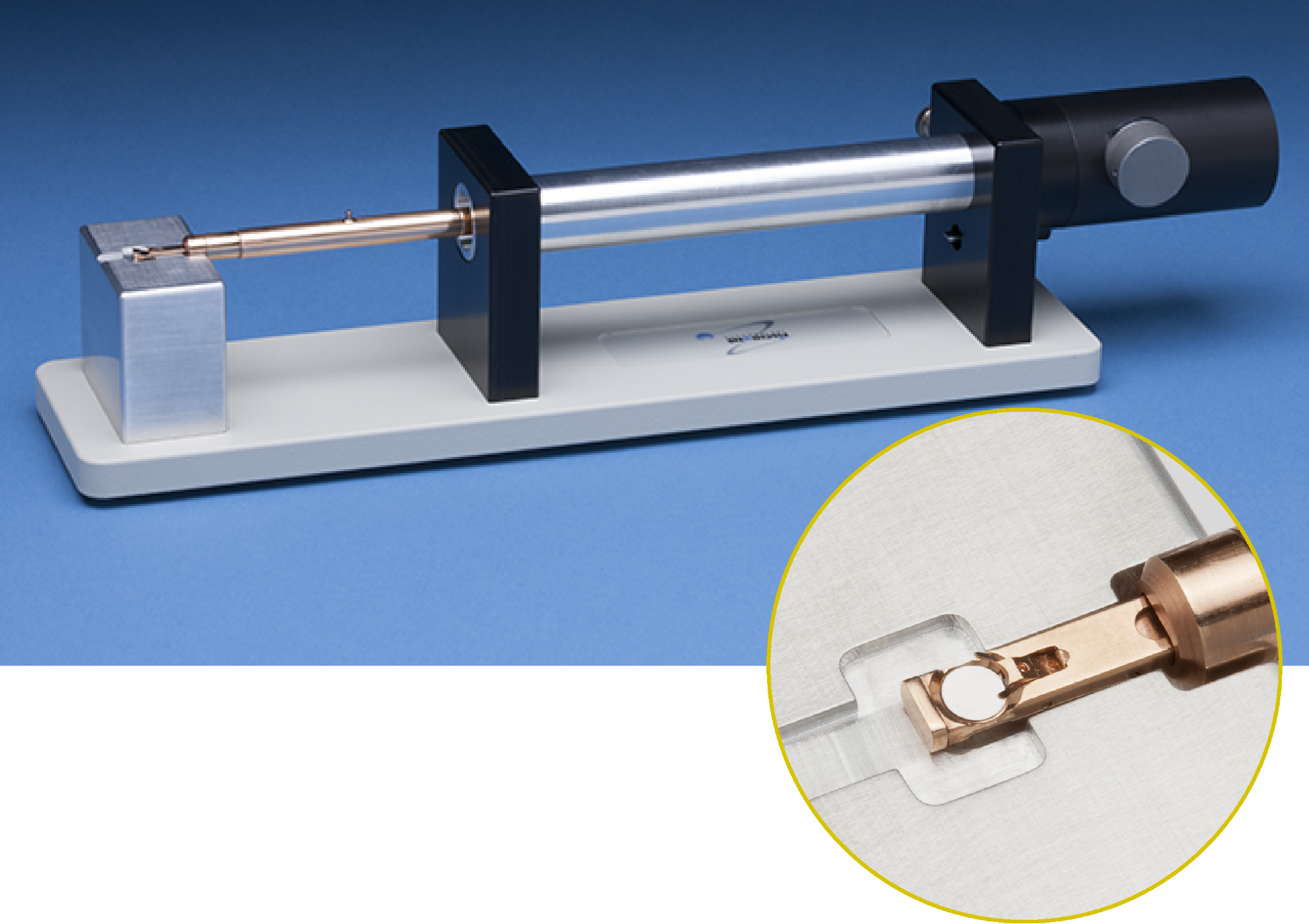

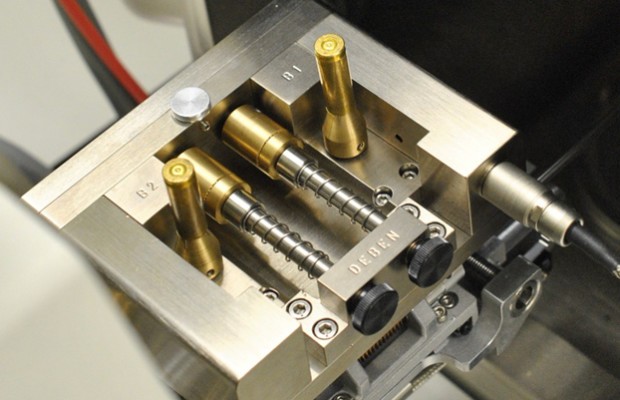

Analyzing and Calibrating Spin Finish with the mqOne

Bruker’s mqOne Spin Finish Analyzer system is an easy-to-operate platform that comes with both Calibration Validation and Calibration Transfer Samples. The Spin Finish Calibration Validation samples check the validity of the validation, which is integral for to precisely and reproducibly quantify low finish concentrations. For most applications, very few calibration samples are necessary. Often, only 3 to 5 calibration samples will be needed for most applications.

Specifications

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-