Application of an elastomer coating on an industrial fiber, also referred to as a “dip on fiber,” is an important component of special fiber applications, including technical, textile, and high performance fibers. Dip on fibers helps to improve several properties of a fiber, including reinforcement, wind stopping, and water repellant properties, depending on the final product’s needs. This coating can also be applied to clothing and rubber products, such as conveyor belts or car tires.

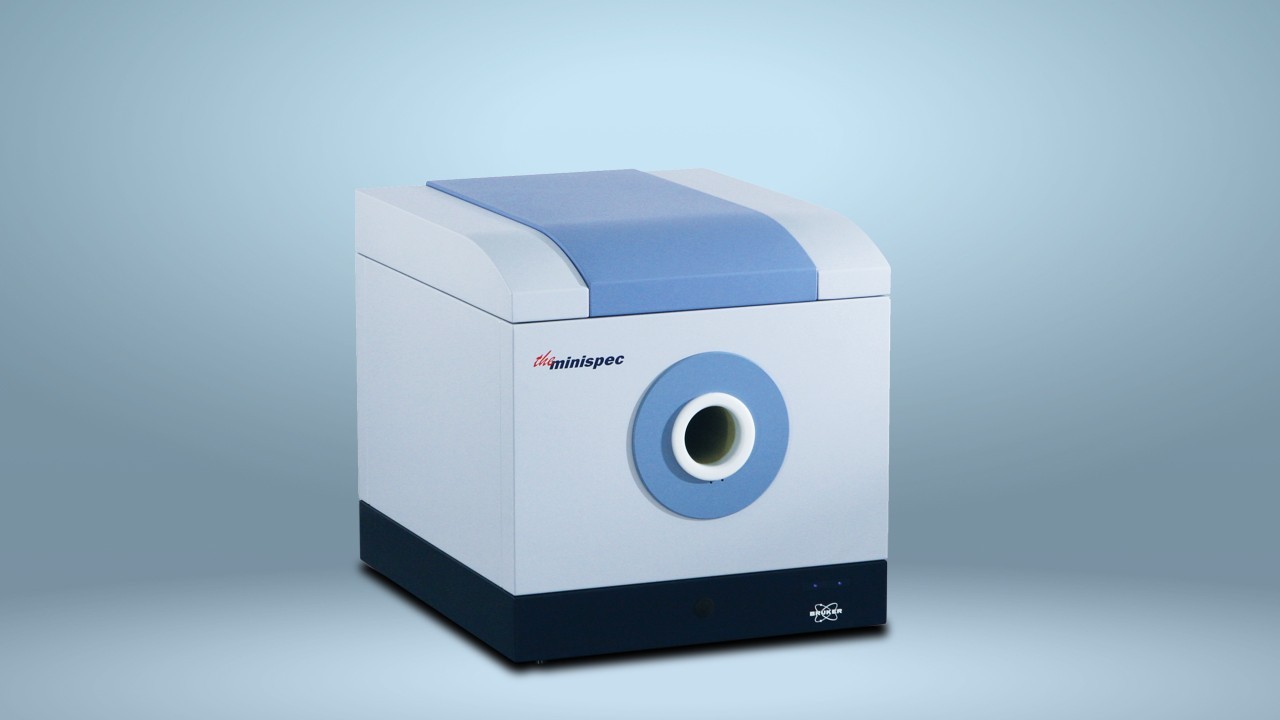

For special fiber applications, an elastomer coating, so-called dip, is necessary to improve the fiber’s proper-ties such as wind stopping, water repellent, and rein-forcement. Such additional properties also qualify the fibers for technical use, for example, for clothing and for rubber products like car tires or conveyor belts. Using the minispec, the dip amount on fibers can be quickly and accurately analyzed in a one-step measurement.

What is a Dip on Fiber?

A dip on fibers is basically a polymer that exhibits elastic properties. Often, these coatings consist of carbon, silicon, oxygen, and hydrogen. Elastomer coatings feature viscoelasticity as well as very low inter-molecular forces. Dips, when applied to fibers, are coatings that seal, behave as an adhesive, and protect the flexibility of objects. Sometimes, these coatings can be used to protect shoe soles, cover tires, and even insulate certain controlled environments.

The amount of dip ranges between 5% and all the way up to 25% in weight, depending on the fibers, coatings, and applications. Applicable material for dip on fibers include:

- Technical, textile, and high-performance fibers

- Multifilament or monofilament fibers

- Polyester, polyamide, polypropylene, polyethylene, polyacrylonitrile fibers

Features

- Very few calibration standards necessary (3 – 5)

- Independent from sample color or surface

- One step measurement in < 60 sec guaranteed

- High reproducibility given, due to excellent magnet and magnet temperature stability

Benefits

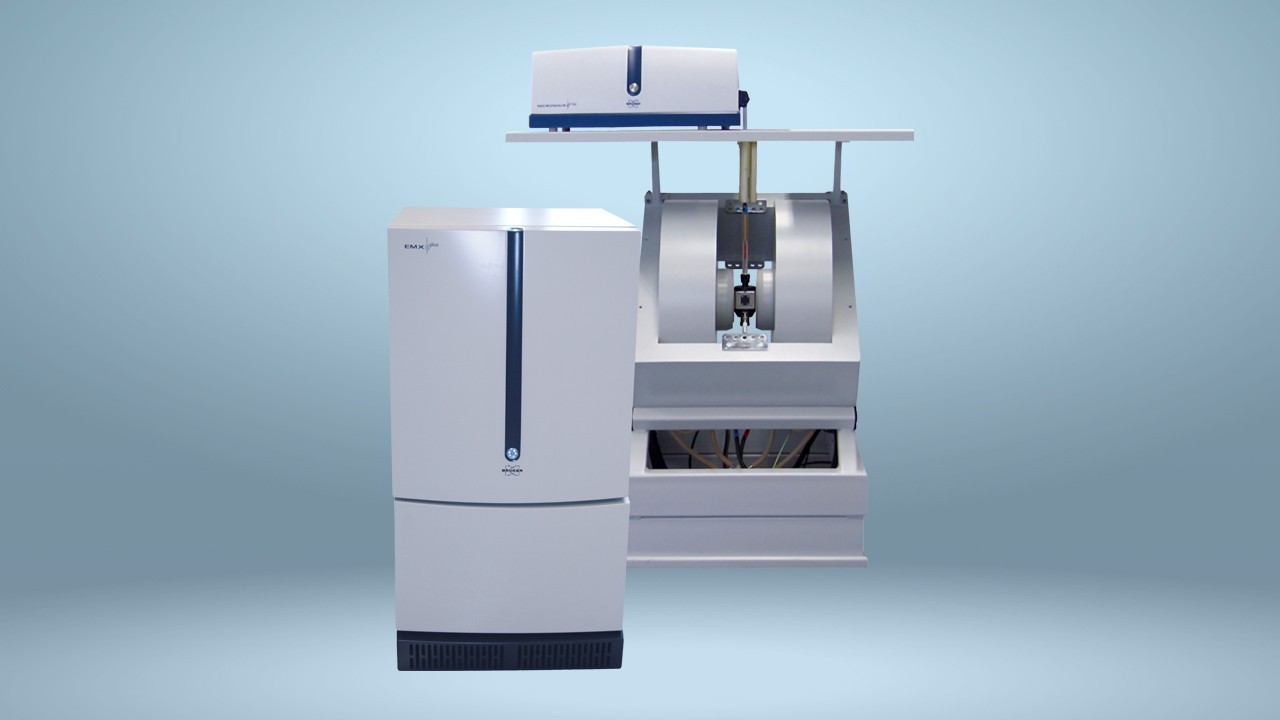

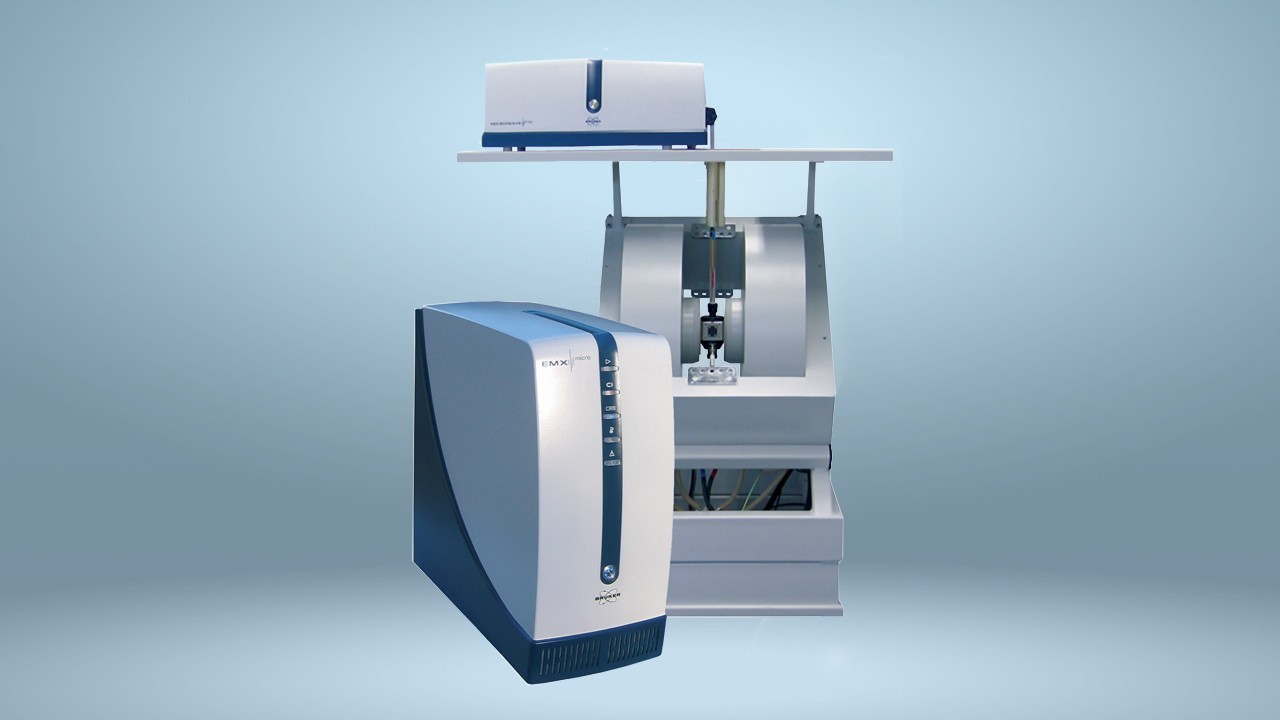

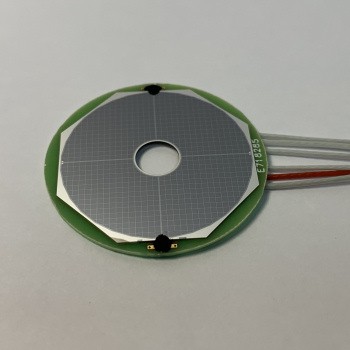

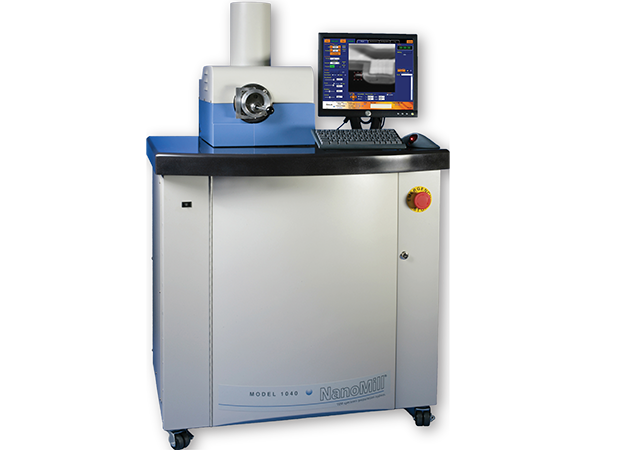

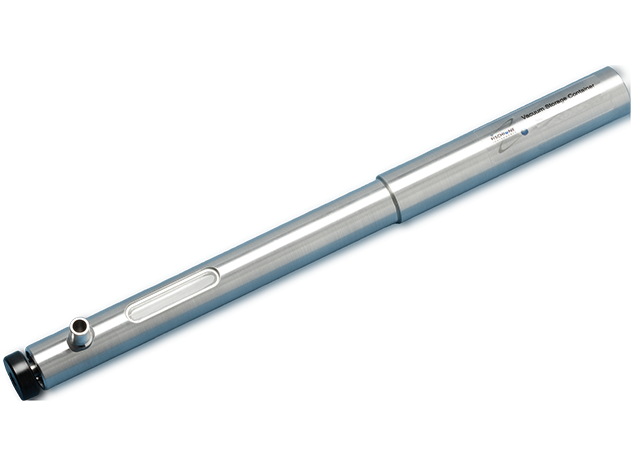

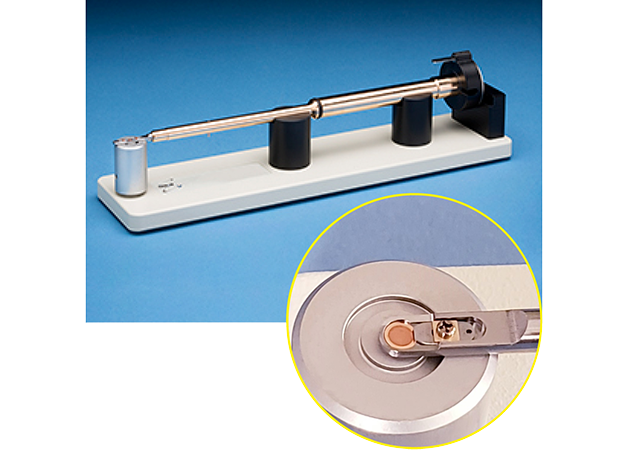

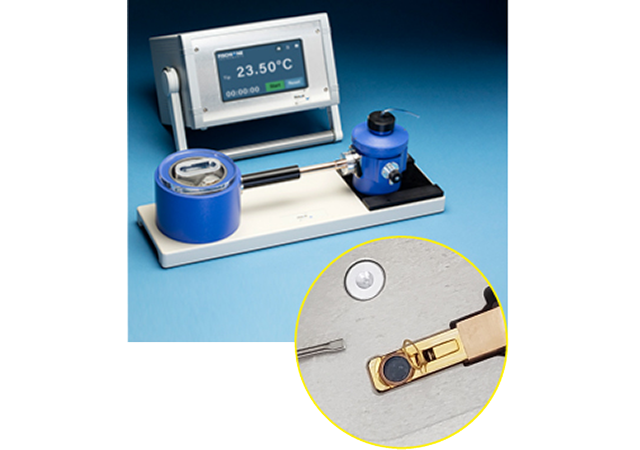

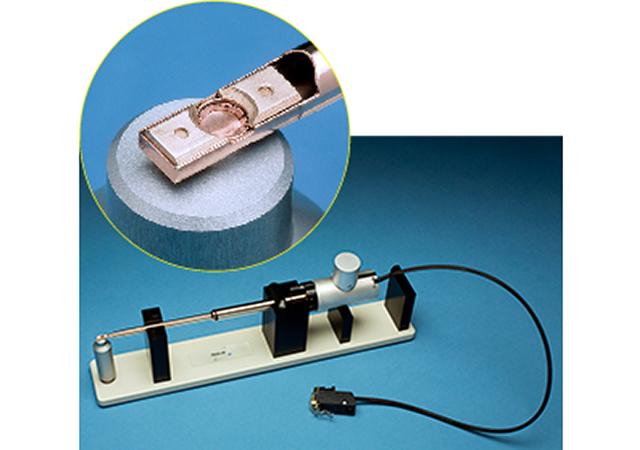

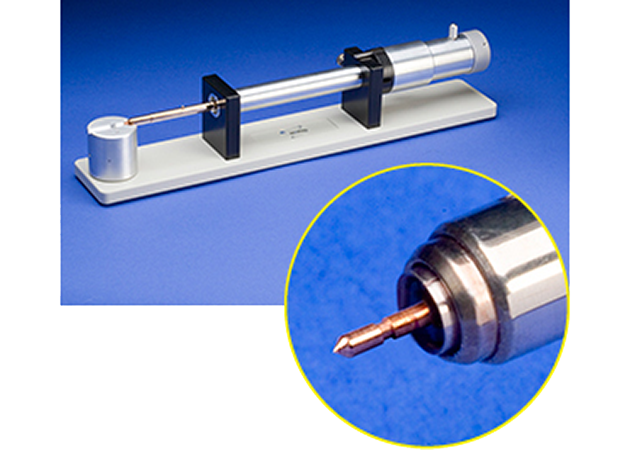

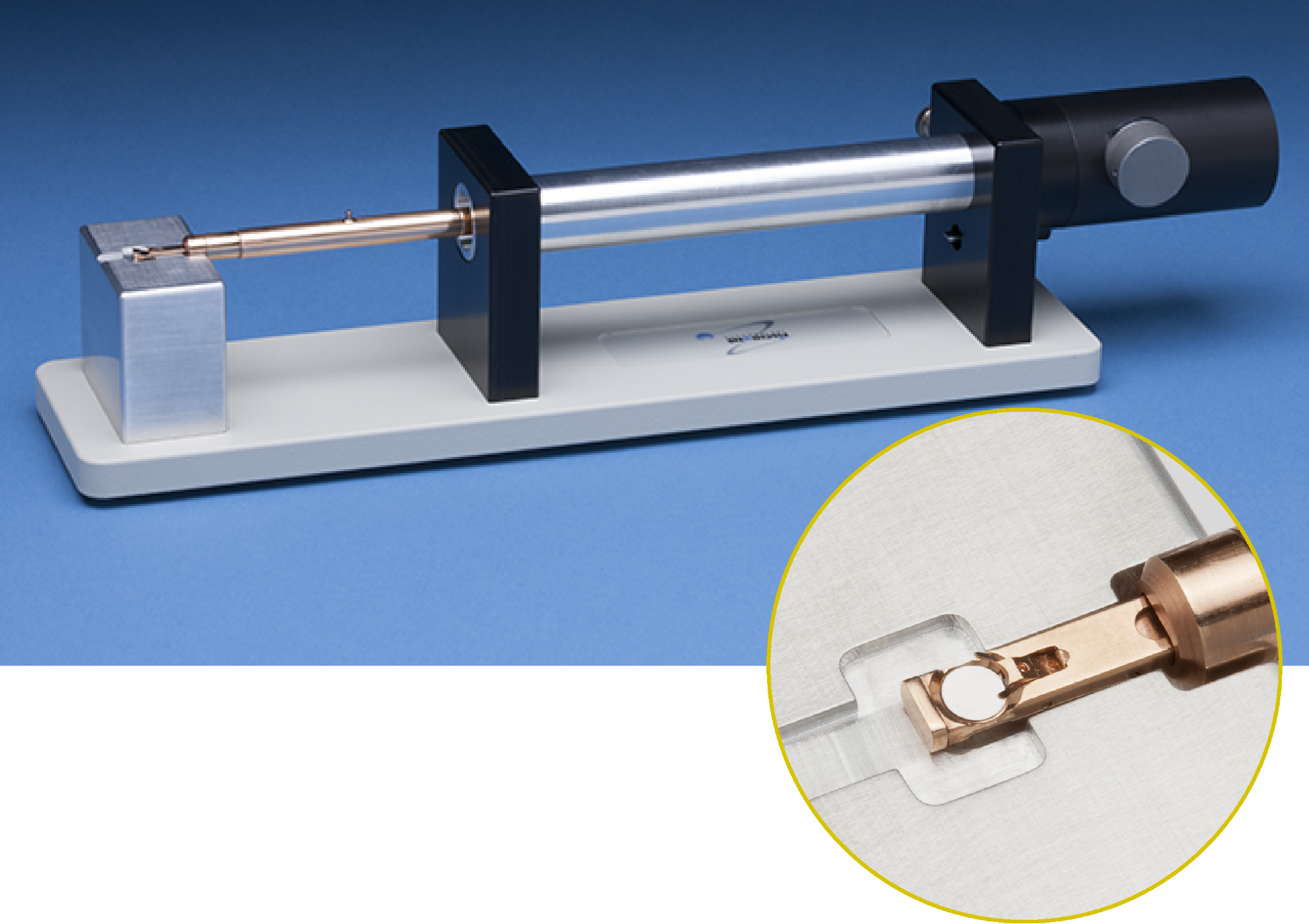

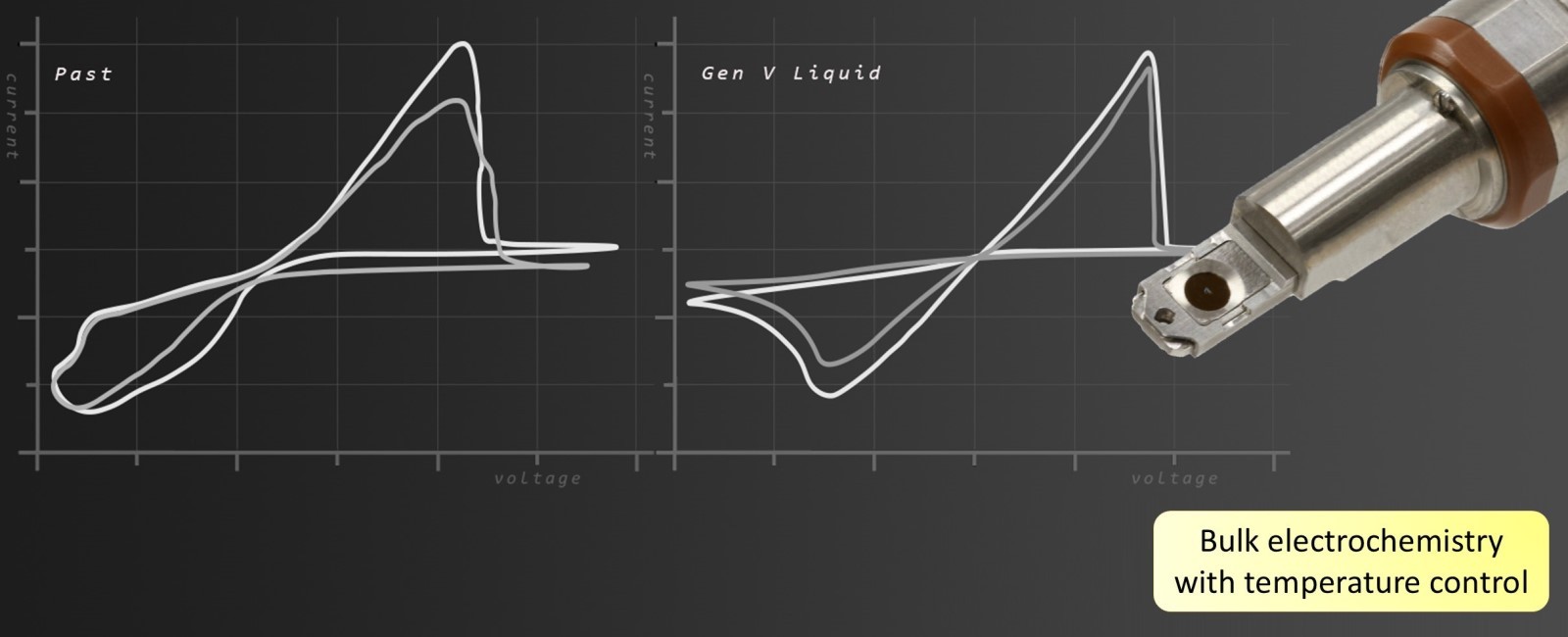

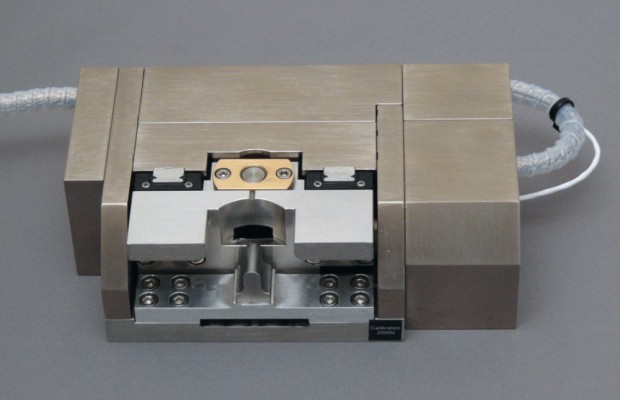

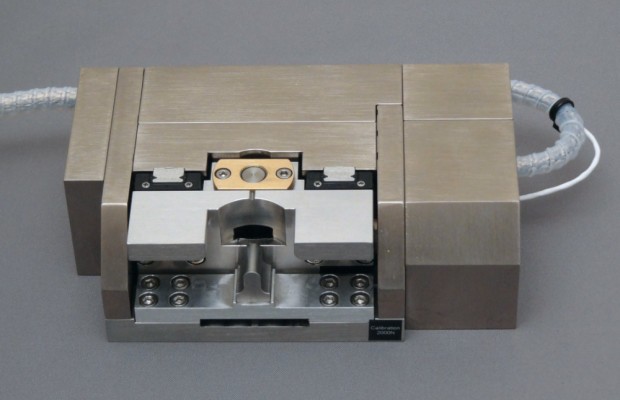

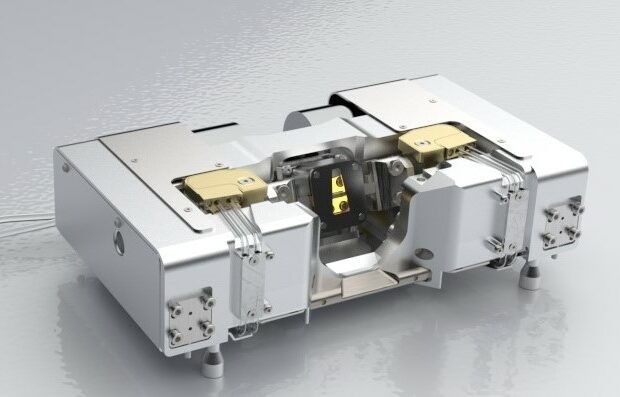

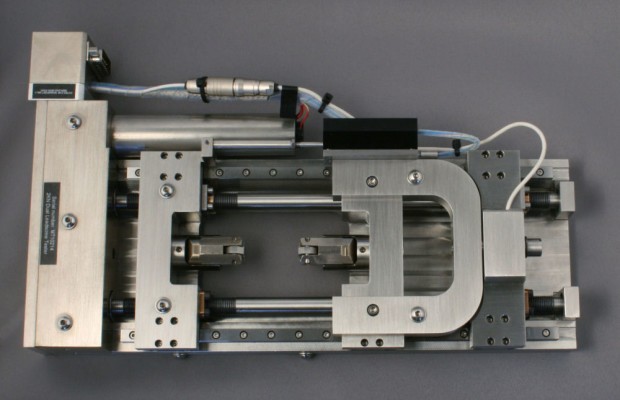

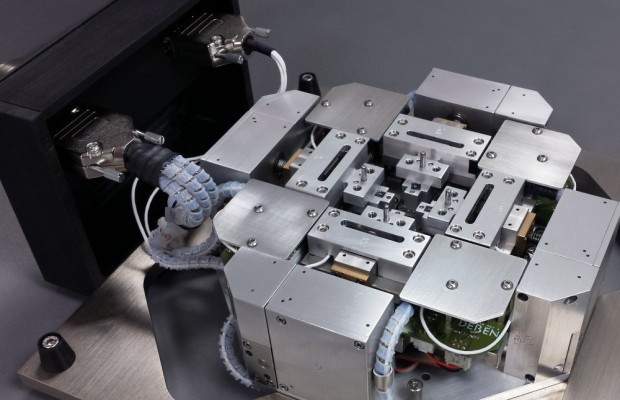

Bruker’s mqOne minispec can quickly and accurately analyze the dip amount on fibers in a one-step measurement. Typically, the application dip coated on fibers is based on varying relaxation times of the fiber and the dip. To analyze the dip amount with mqOne system, the fiber sample is first weighed in a tube to determine the sample mass. The system measures the decay of the time-domain (TD) NMR signal of the coated fiber. The dip signal is separated from the fiber signal, with the amplitude correlating with the dip amount.

The Bruker’s minispec system offers several advantages over other analytical methods, such as wet chemical analyses, near infrared, and gravimetry. One benefit of the mqOne system for analyzing dip on fibers is that very few calibration standards or necessary. Additionally, the system offers a one-step measurement in a guaranteed timeframe of <60 seconds. The mqOne also offers a high level of reproducibility, primary due to excellent magnet and magnet temperature stability.

Applications

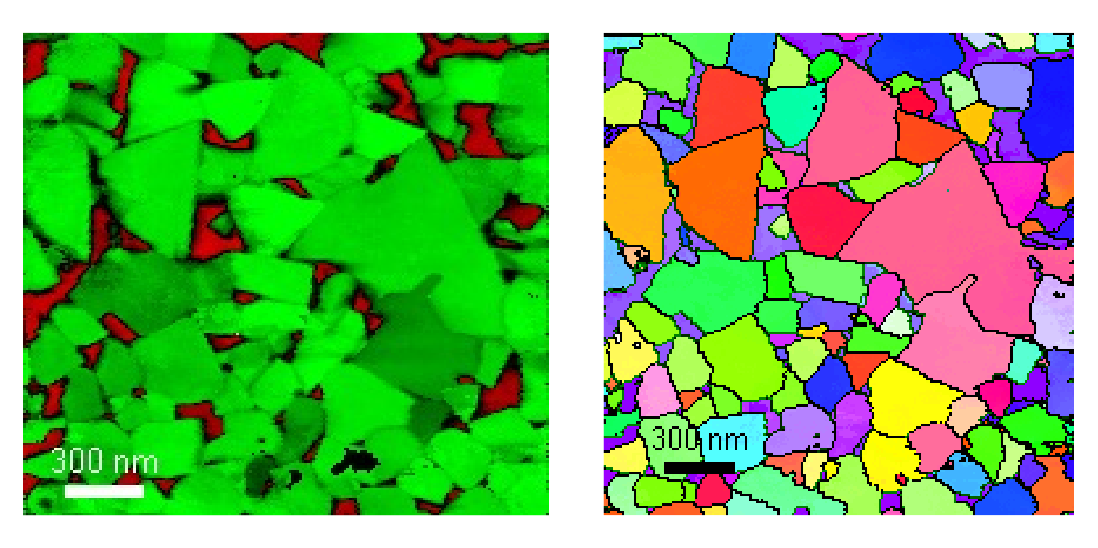

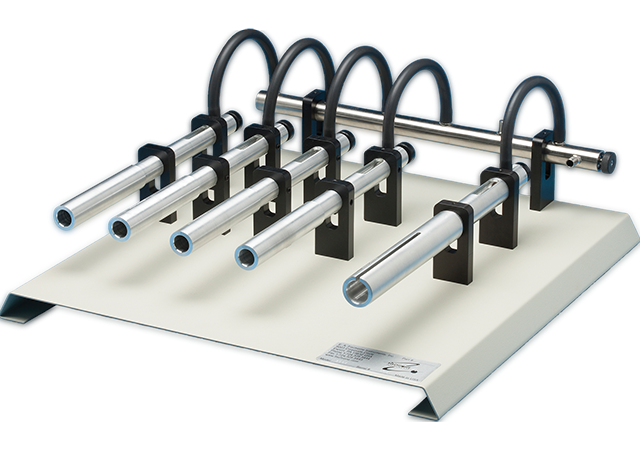

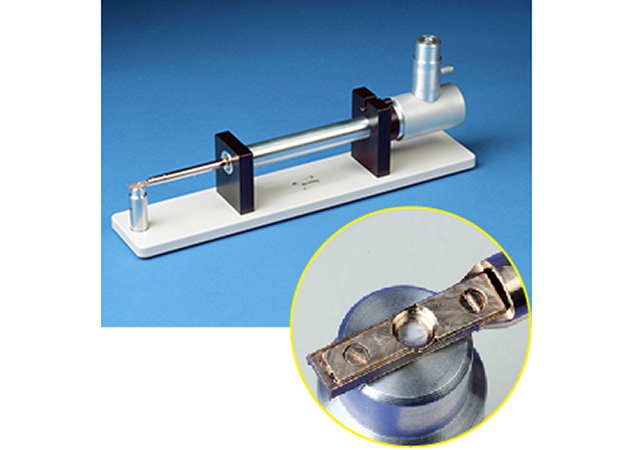

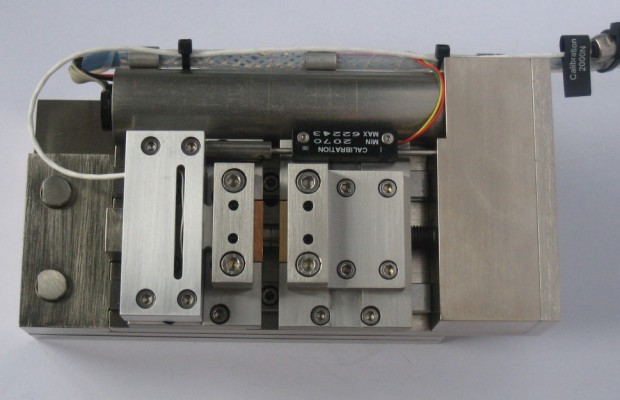

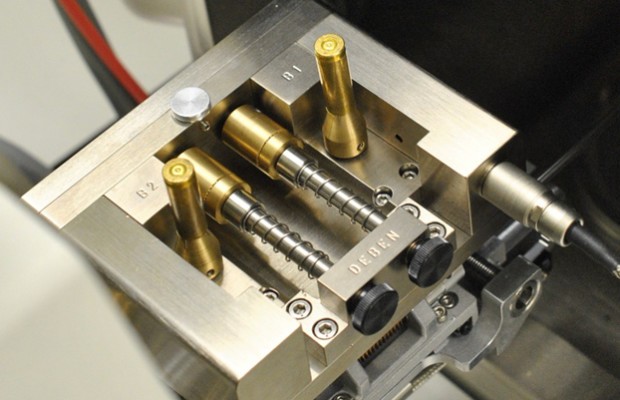

For analyzing the dip on nylon fibers, 5 samples of known dip contents were measured for calibration. For each sample two replicates were prepared. The 18 mm sample tubes of the minispec mq20 Spin Finish Analyzer were filled with approximately 5 g of the sample and were tempered at 40°C prior to measure-ments. The reference values were determined using gravimetry. The comparison between TD-NMR and gravimetry is remarkable: the results are almost equal to the reference values, see figure below

Example Analytical Technique

In an analysis of the dip on nylon fibers, a total of 5 samples of known dip contents were measured for calibration. The operator prepared two replicates for each sample. Then, the operator filled 18 mm sample tubes of the mqOne Spin Finish Analyzer with around 5 grams of the dip sample. These tubes were tempered at 40 degrees Celsius. Gravimetry was used to determine the reference values. Then, a comparison was made between the TD-NMR and gravimetry, which revealed roughly equal results to the reference values.

Analyzing Dip on Fiber

Analysis of dip on fibers can be important to determine whether or not the product is appropriately sealed and/or coated prior to release to market. While it’s an important part of the manufacturing process, determining the appropriate levels of dip on fibers is not always easy. In some situations, the analysis of coating levels needs to be accomplished quickly and continuously, which warrants the need for improved methods of assessment.

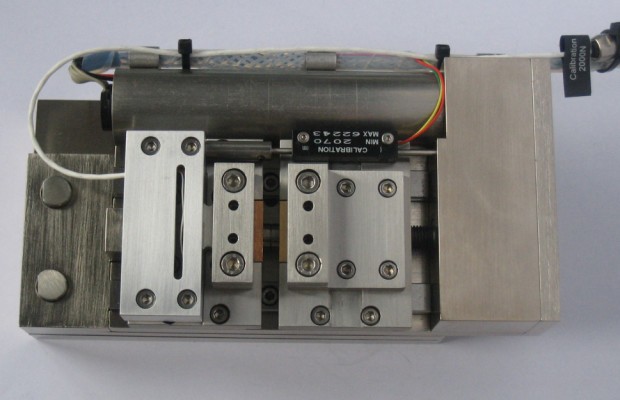

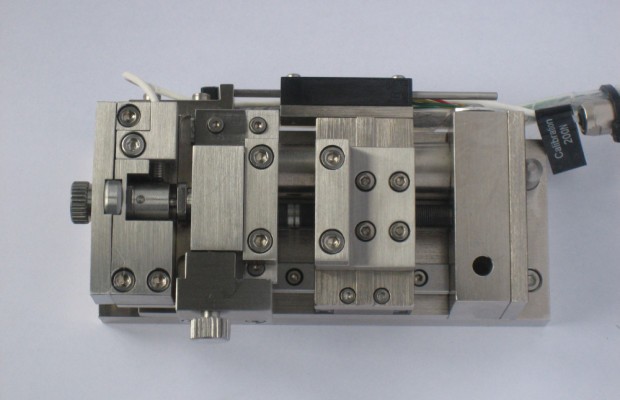

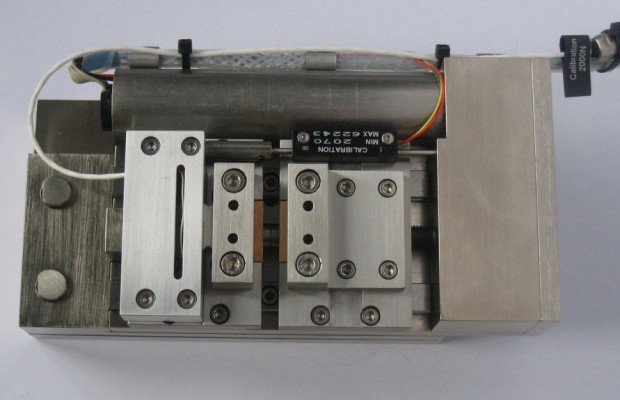

Bruker’s easy-to-operate mqOne Analyzer system is one platform that can be used to analyze dip on fiber in various fibers and products. The system comes with both Calibration Validation and Calibration Transfer Samples. Very few calibration samples are necessary for the majority of applications, as only 3 to 5 calibration samples are needed in most instances. Overall, the entire workflow – from weighing the empty sample tube to produce a results report – clocks in just under 5 minutes, depending on the application.

Specifications

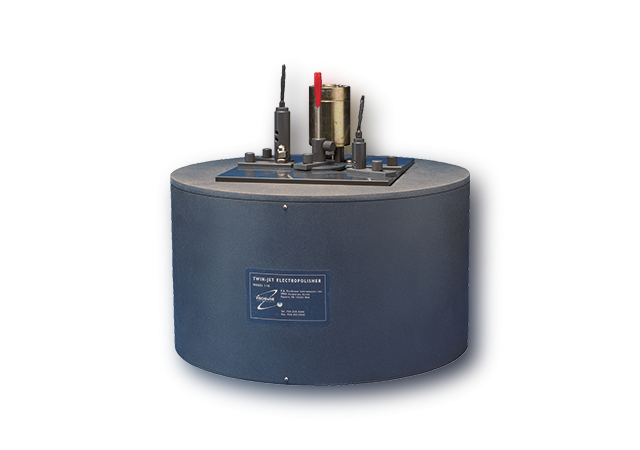

- minispec mq-one Spin Finish Analyzer for routine

- minispec mq20 for R&D and routine

- Multilingual m+ software with fully traceable data

- Glass or TEFLON® tubes

- Balance with automatic weight transfer to minispec software

- Metal block thermostat for sample pre-tempering (optional)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-