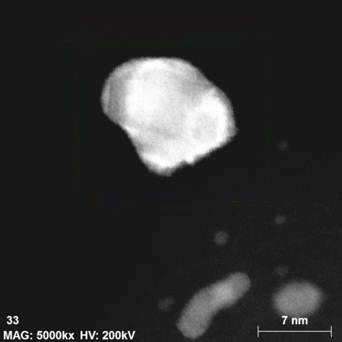

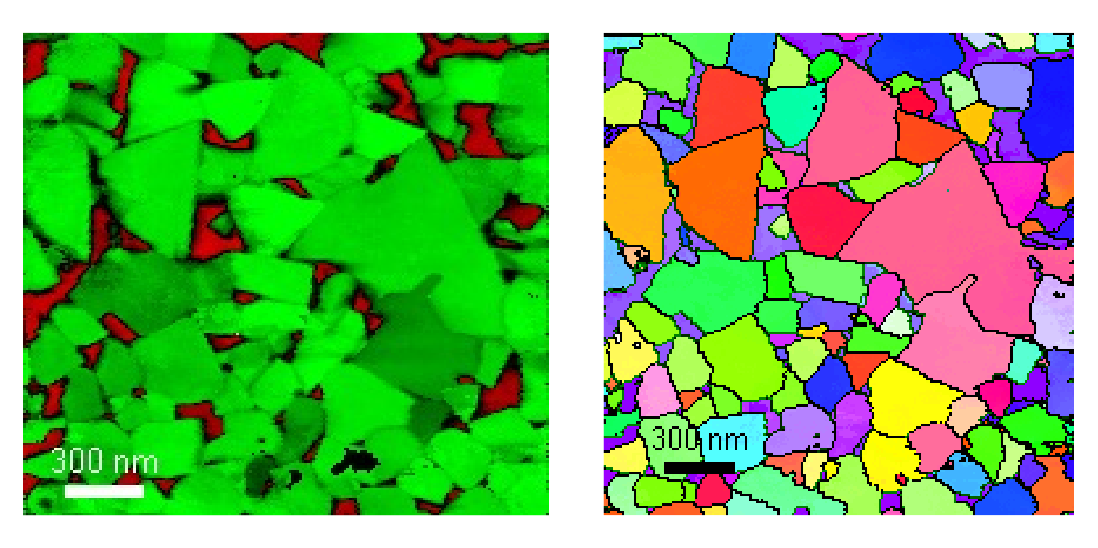

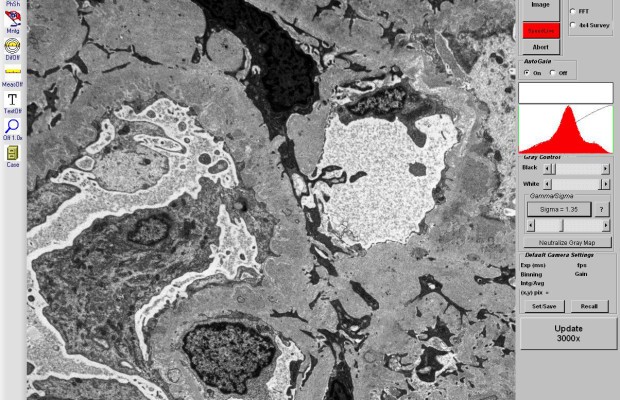

Single Atoms and Nanostructures

Get the Best Possible Results for each Specific Microscope

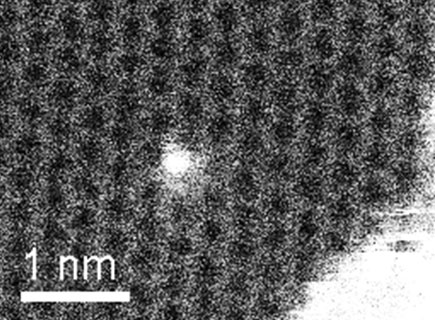

80keV

1 Å

3 TEM-quantification models

Element Analysis in Transmission Electron Microscopy on the Nanometer Scale

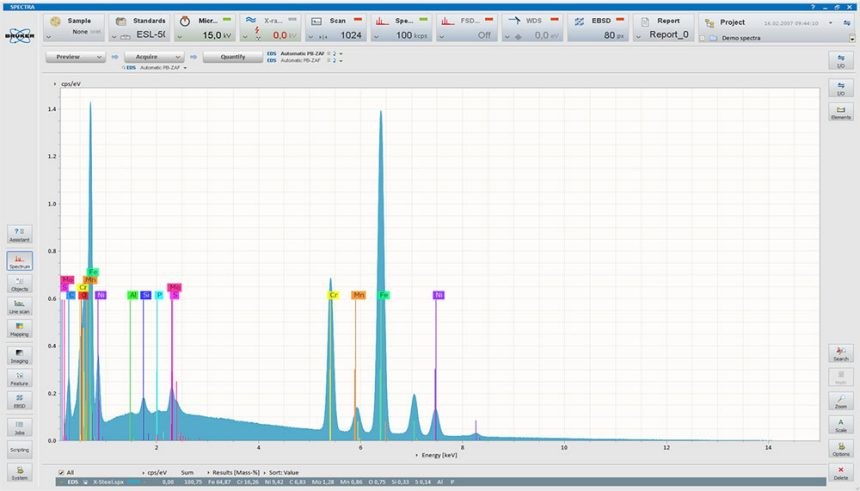

Flexible and easy-to-use analysis software package ESPRIT with an open user interface: you see what you do.

Off-line analysis option with individual or LAN access for student or laboratory networks.

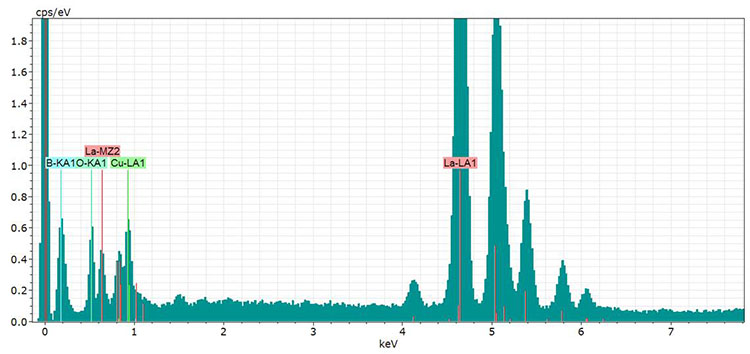

Sophisticated most seasoned quantitative energy dispersive X-ray spectroscopy (EDS) for complete data mining includes:

- Options for quantification steps: default suggestions for easy use, indvidual setup, detailed modification and saving/reloading of recipes

- 3 different quantification approaches are covering all possible scenarios based on theoretical and experimental Cliff-Lorimer factors as well as Zeta-factors and the interpolation of missing Zeta-factors

- TEM-specific high energy element lines above 40 keV available for quantification ensuring unambiguous results

- Choice of 3 vital background models: a physical one for bulk and a physical one for thin lamellae as well as a mathematical model

- Absorption correction included in the Cliff-Lorimer quantification already

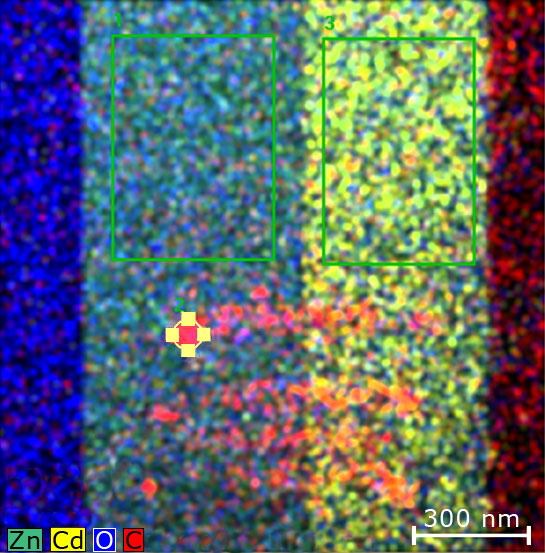

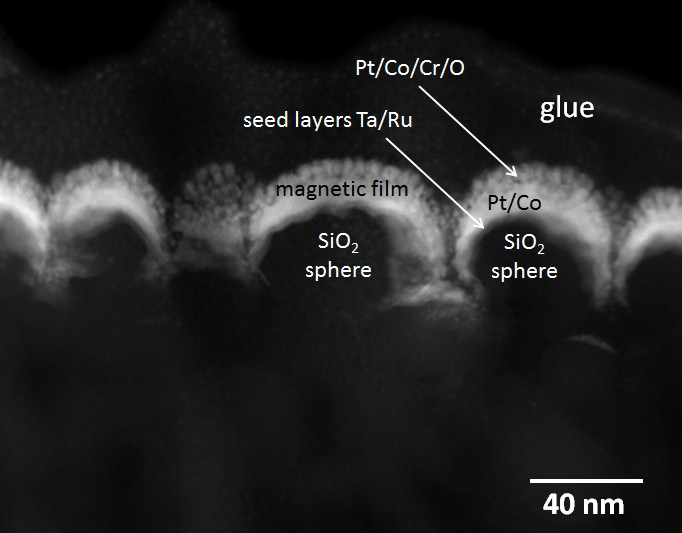

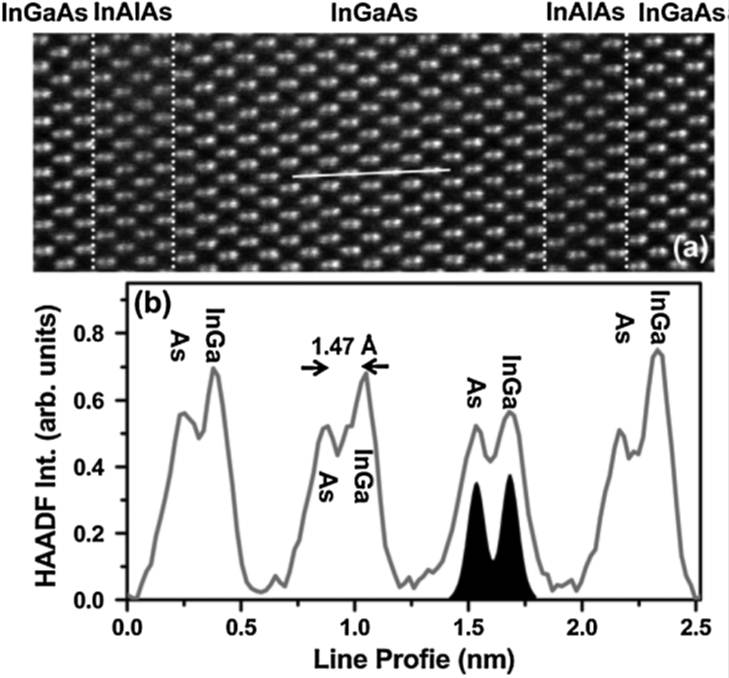

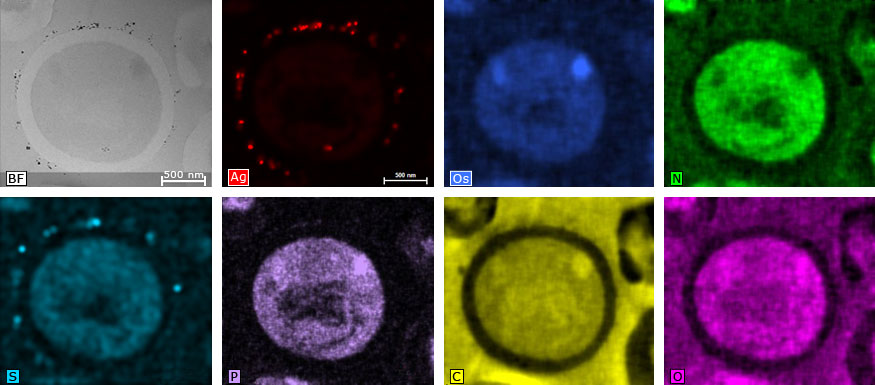

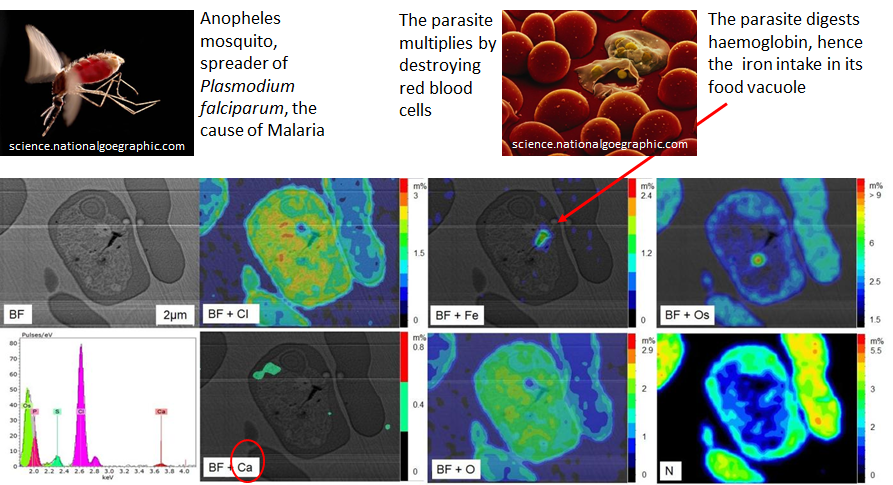

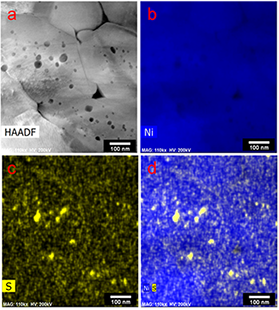

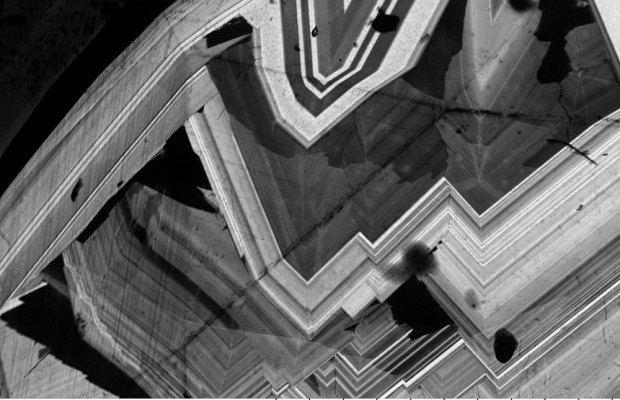

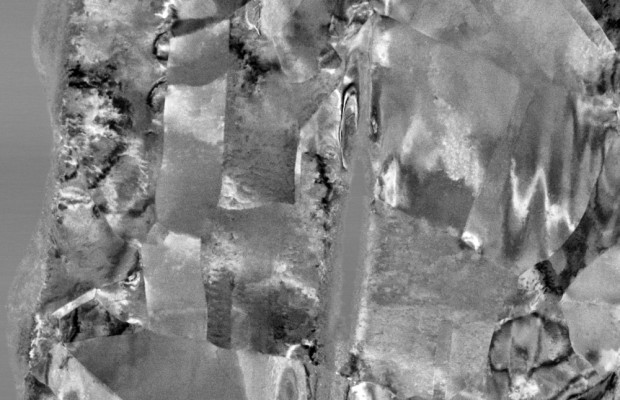

High-resolution Element Distribution Analysis of Electron Transparent Samples in TEM, STEM and SEM (T-SEM)

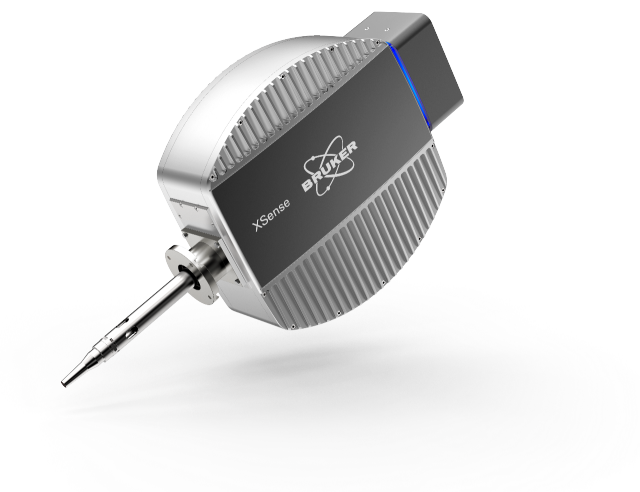

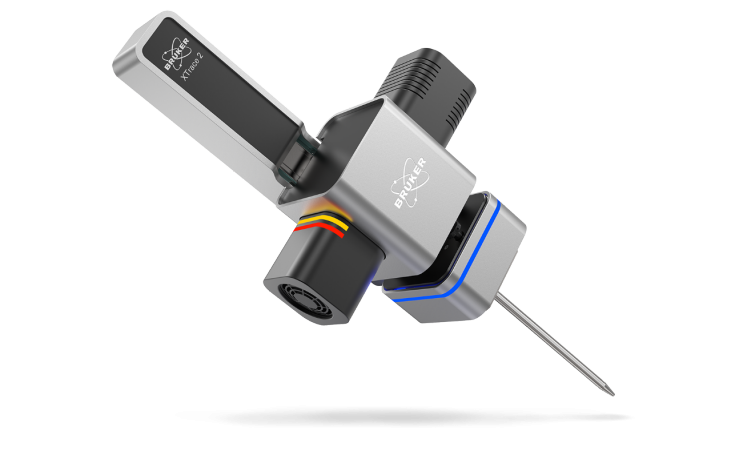

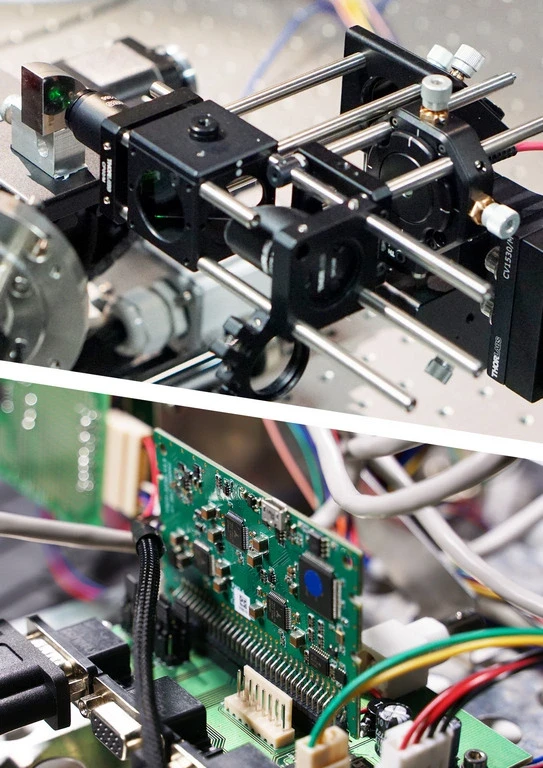

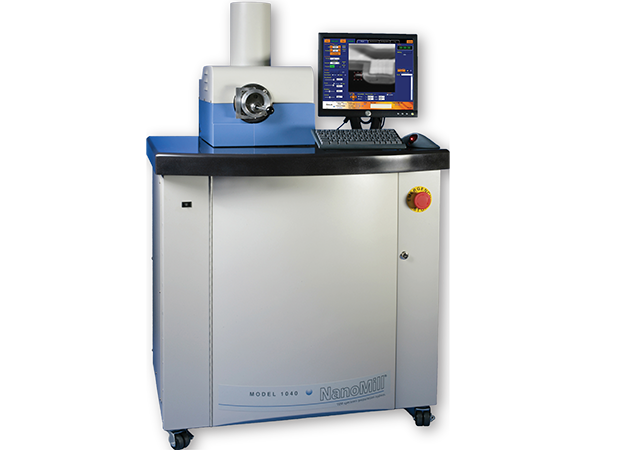

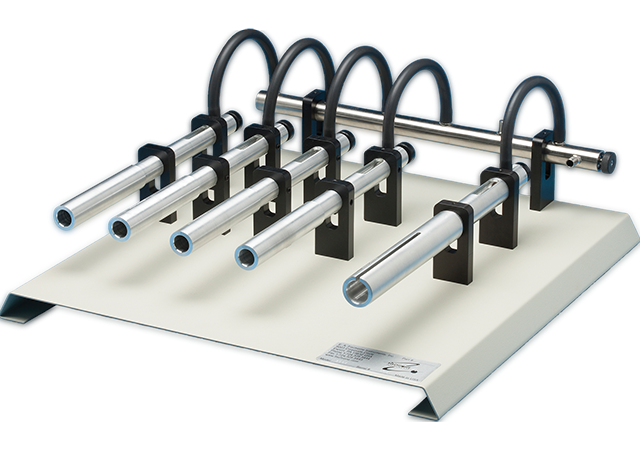

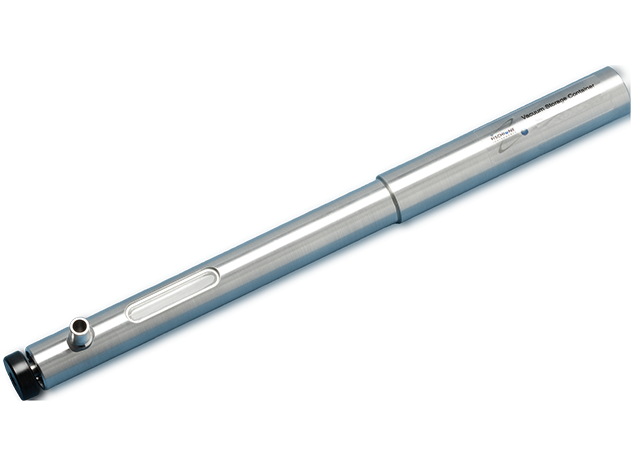

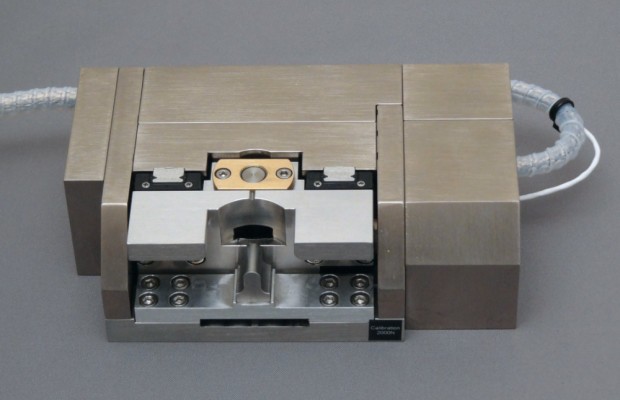

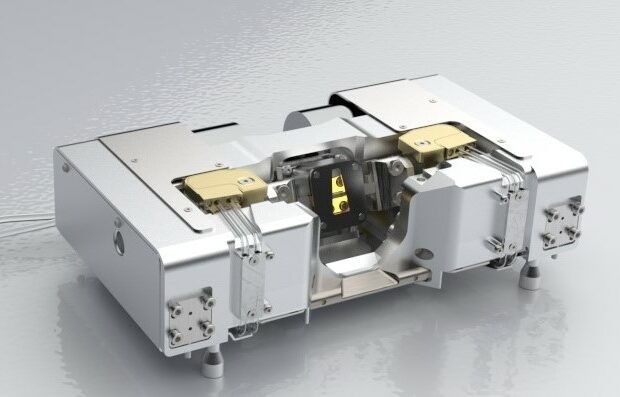

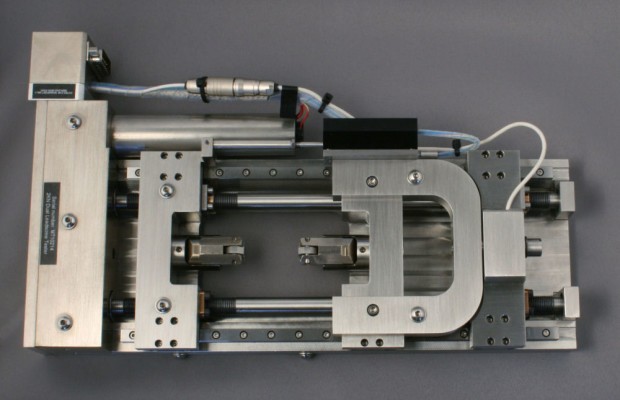

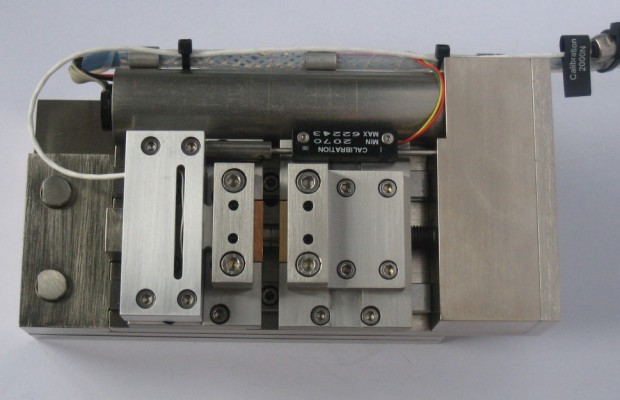

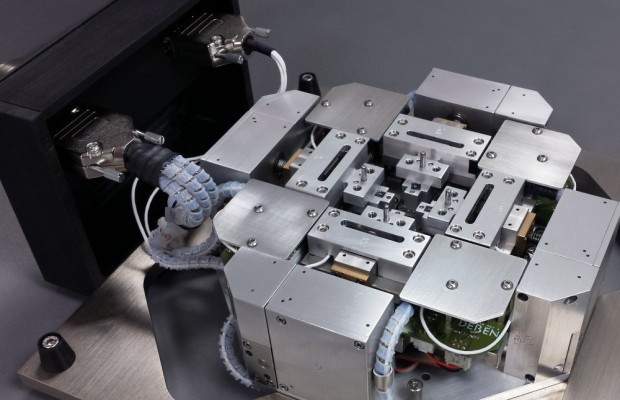

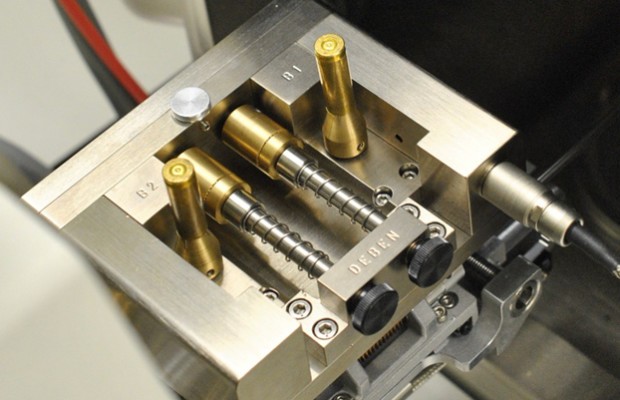

- Long standing expertise in EDS ensures the configuration of the best solution for your specific microscope (STEM, TEM or SEM) thanks to slim-line detector design and geometrical optimization for each microscope pole piece and EDS flange type

- Maximum collection and take-off angle allow fast and highly sensitive data acquisition

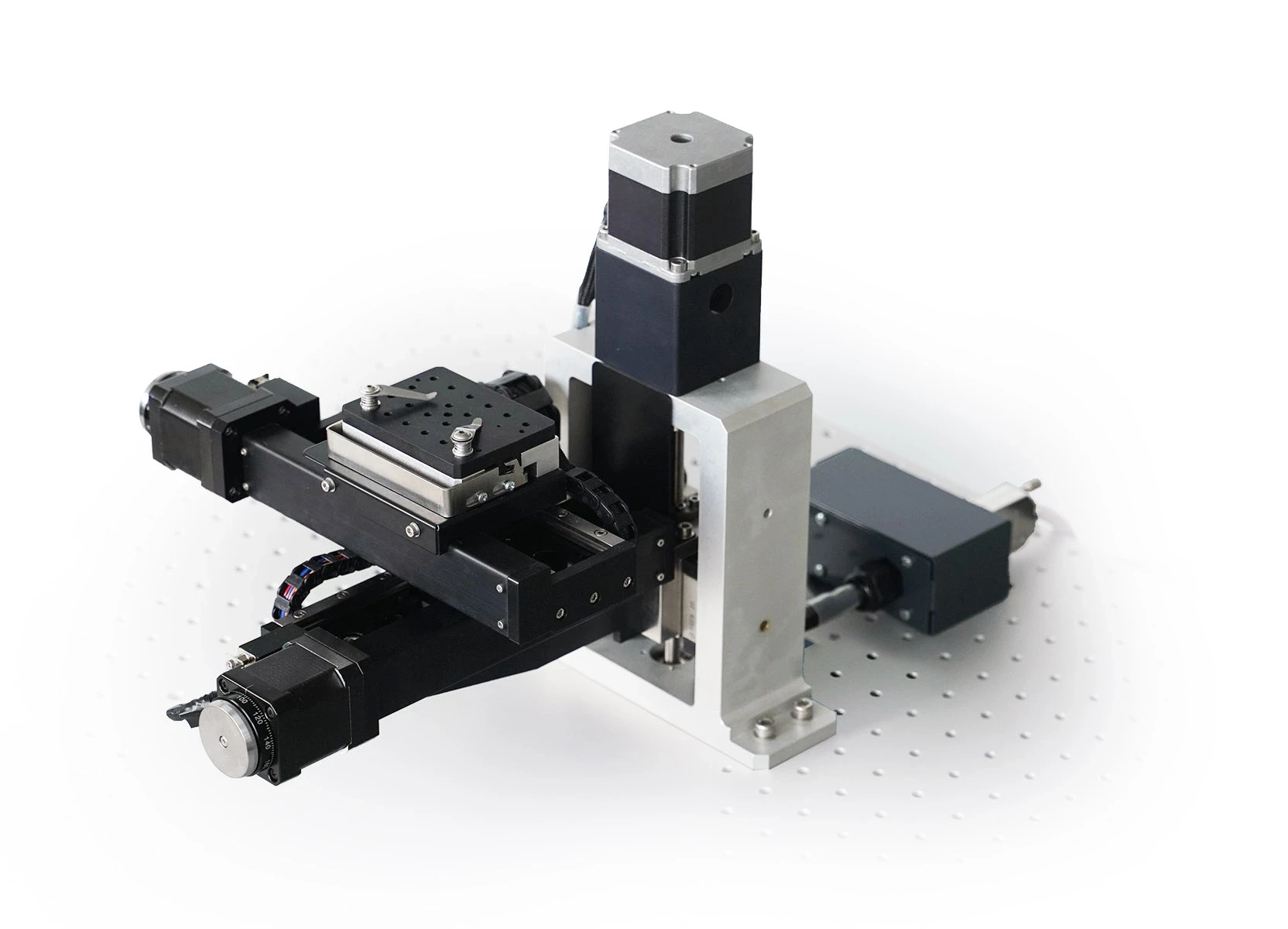

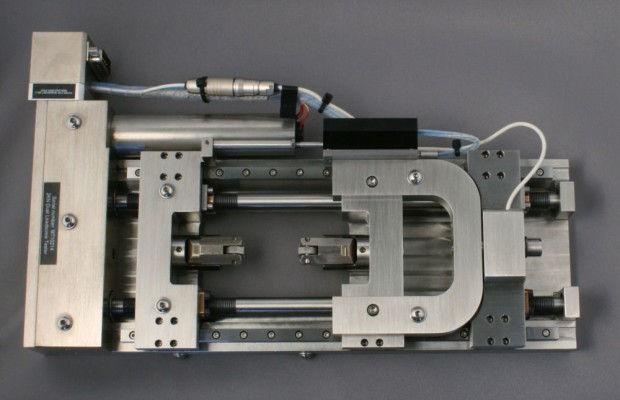

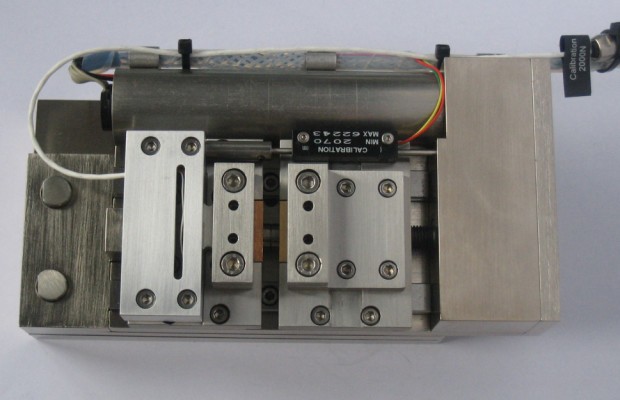

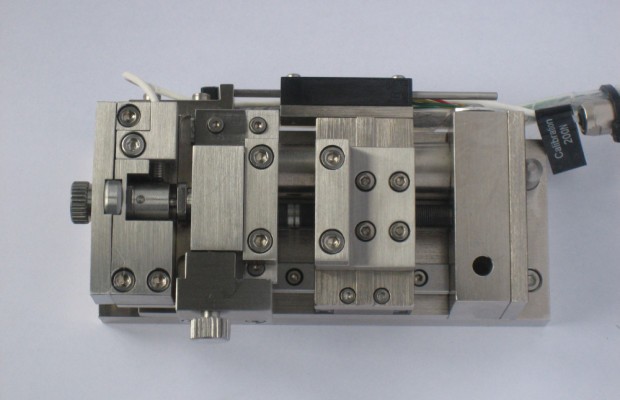

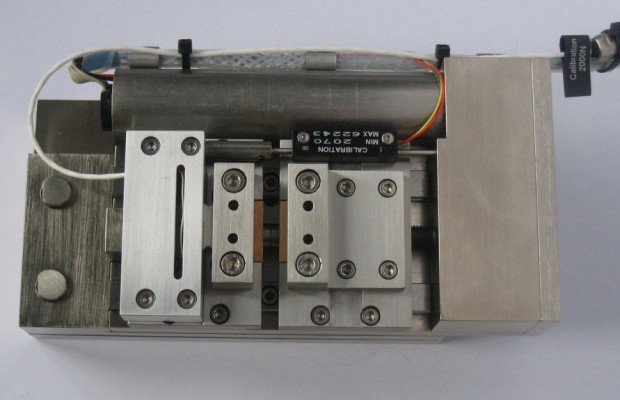

- Fast-moving stable detector stage

- A special drift correction routine for periodic features ensures successful EDS on the nanoscale

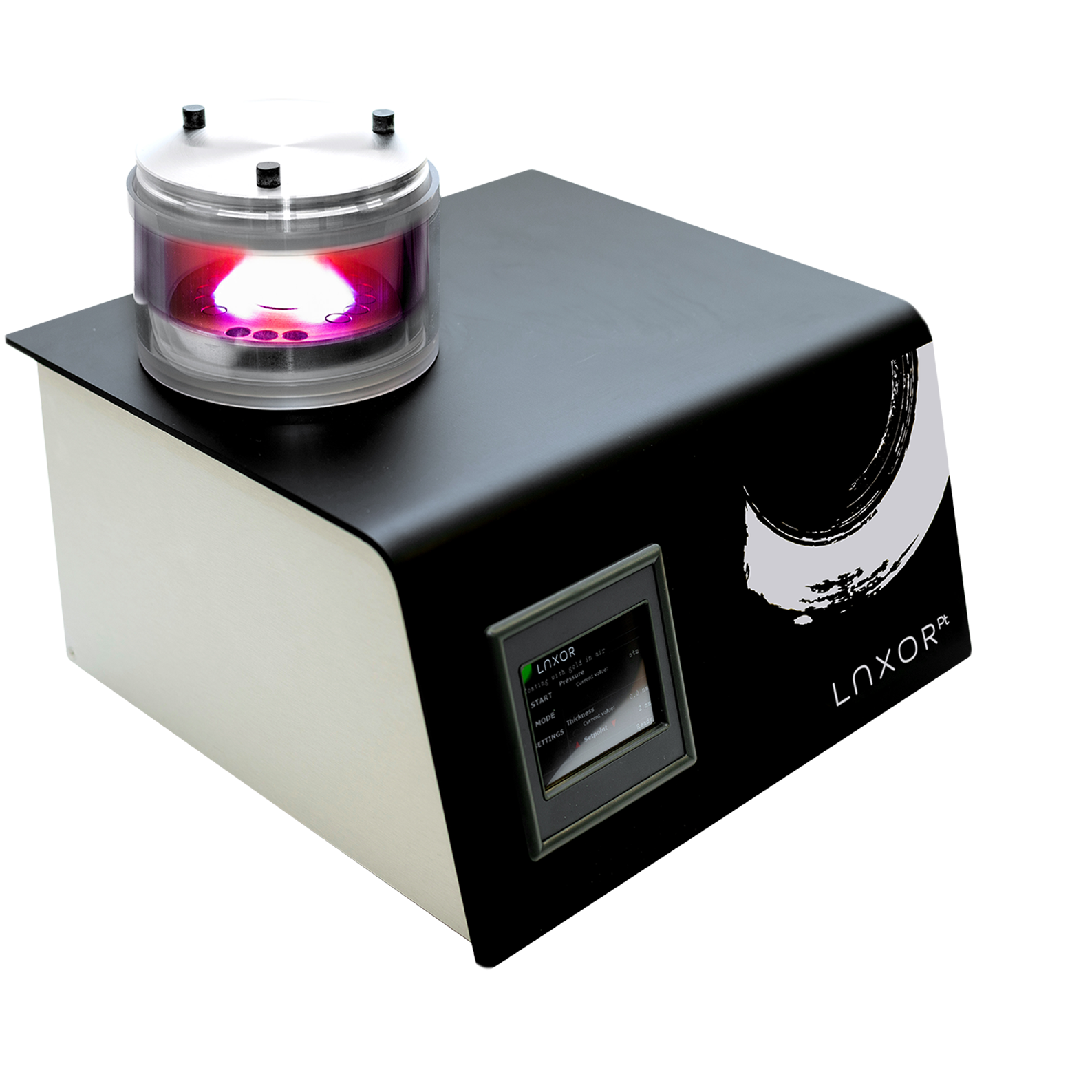

- Time resolved data acquisition for in-situ experiments suitable for saving a stream of changing data, f.e. at elevated temperatures

- Automation of data acquisition and analysis processes using the scripting and API options for generation of specific analysis jobs and batch processing

- Clean data needing no or minimal post-acquisition corrections due to avoiding mechanical and electromagnetic interference completely and avoiding or keeping to a minimum specimen tilt, absorption, shadowing and system peaks

- Most seasoned quantification for EDS data from electron transparent specimens on the market provides thorough data mining with unambiguous results

- Highest quality assistance and training due to long standing experience in TEM for using your system to its full power

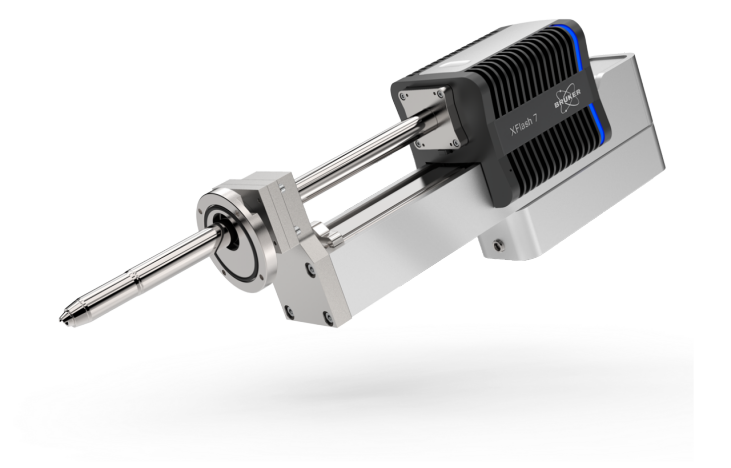

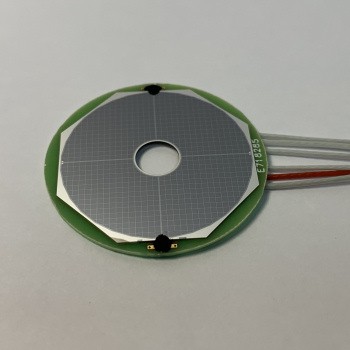

Ultimative Results with the Latest XFlash® 7 EDS Detectors for TEM

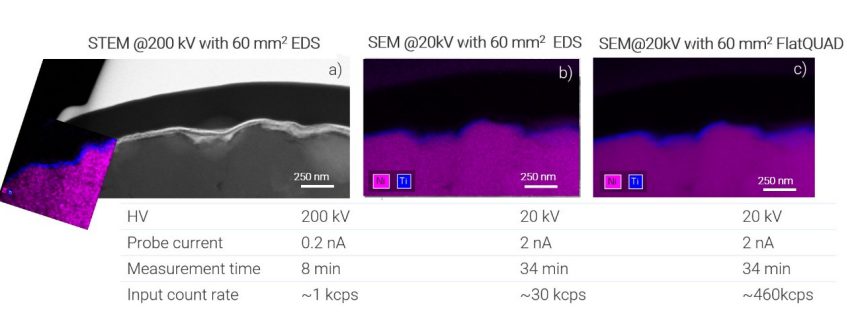

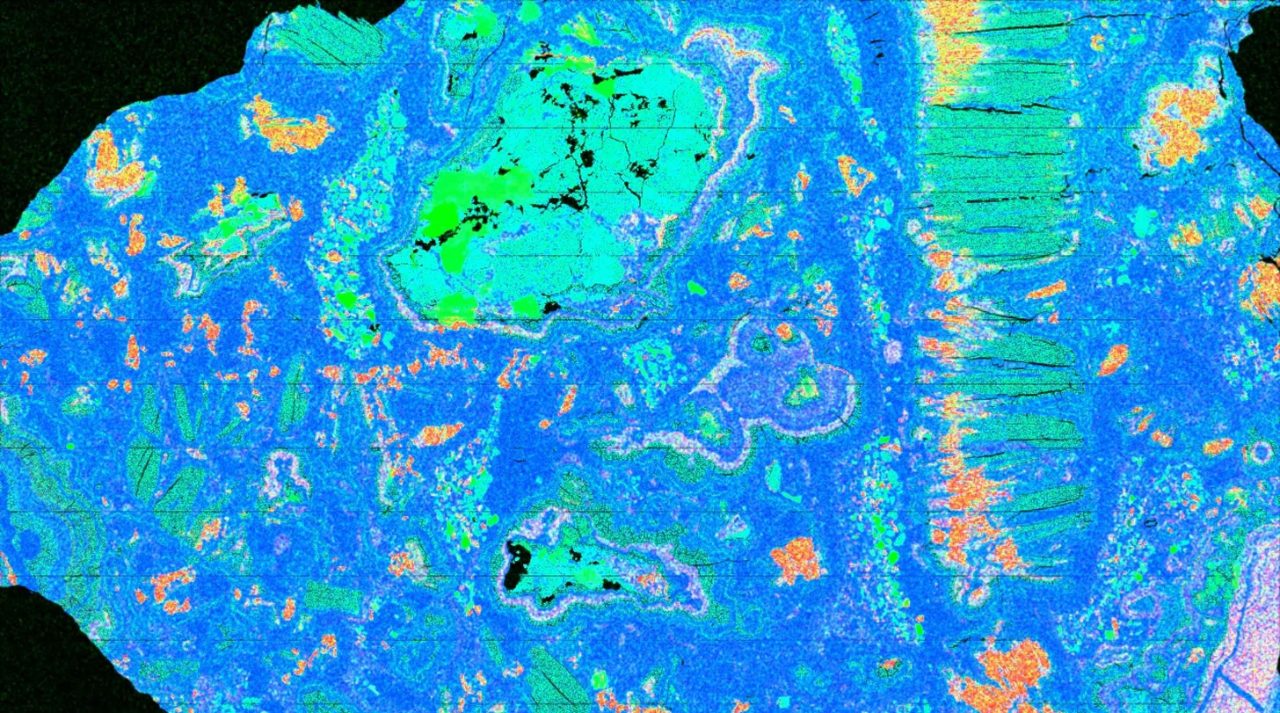

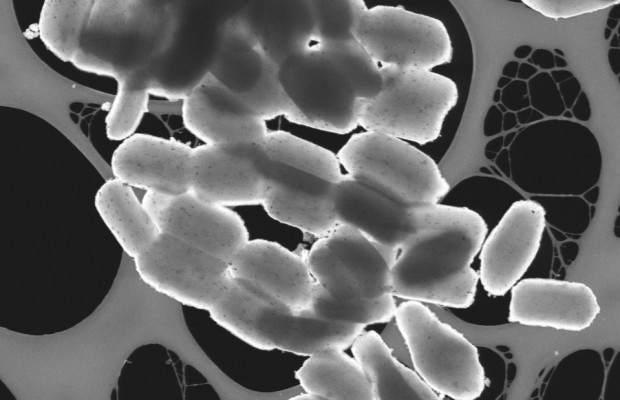

EDS Analyses of Coated Li-ion Battery Cathode Particle

The capacitance retention of NCM cathode material of batteries (SSB and LIB) can be improved by coating structures. To control the performance of these nanometer-thick coatings, their elemental distribution must be known. We present a SEM-based solution of EDS analysis achieving nanometer resolution on micrometer-sized cathode particles with irregular surfaces and compare it to TEM EDS.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-