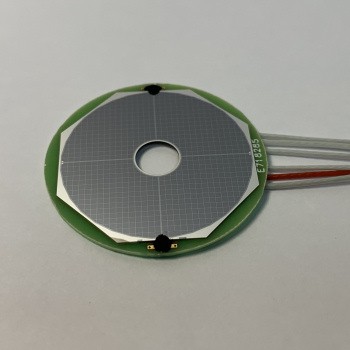

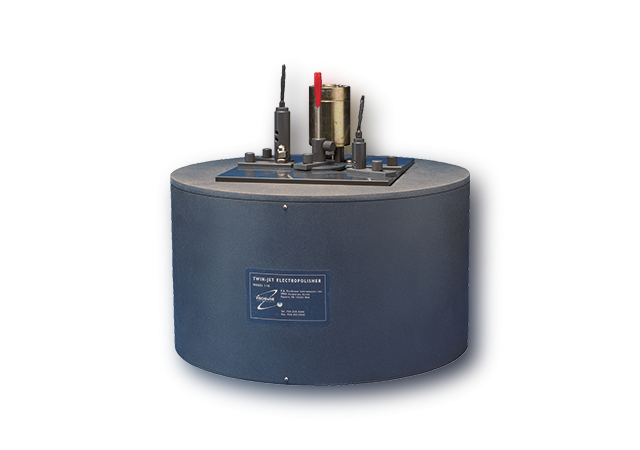

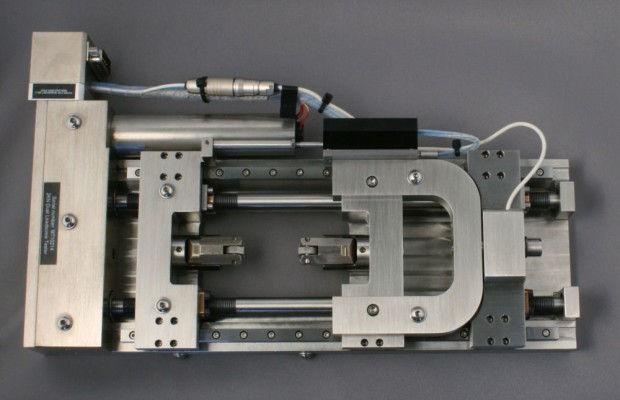

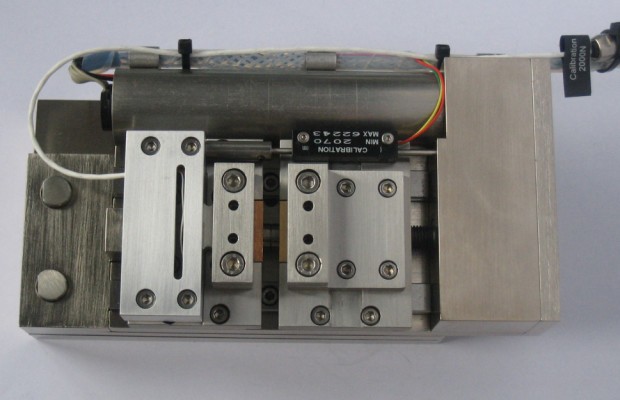

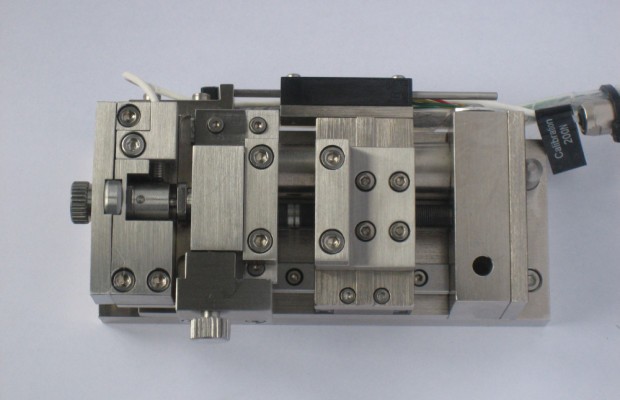

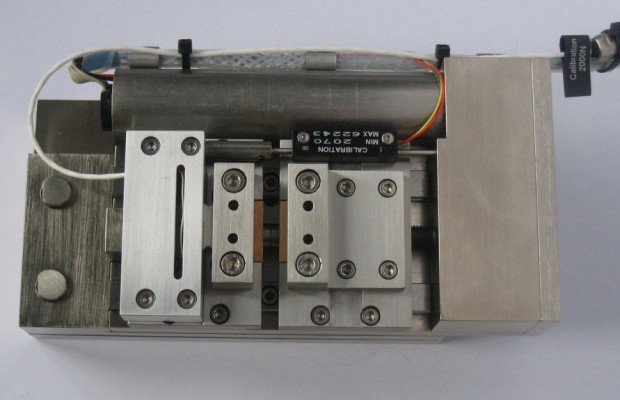

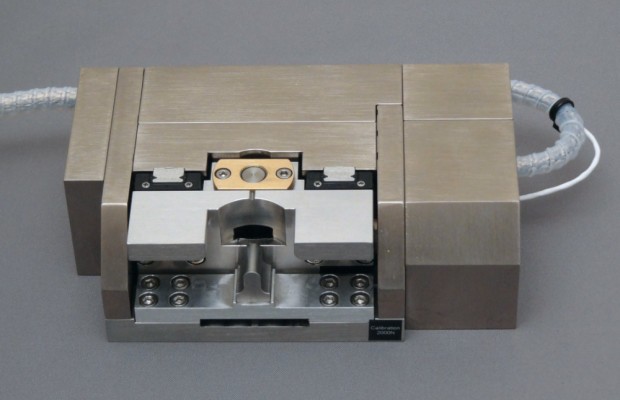

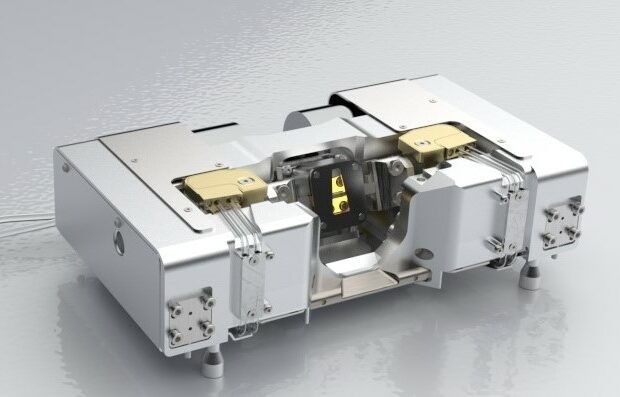

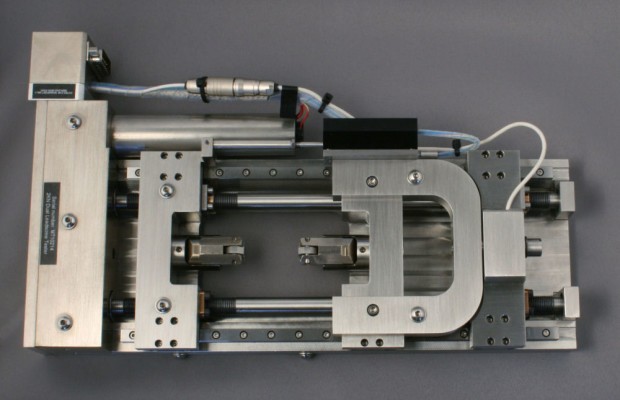

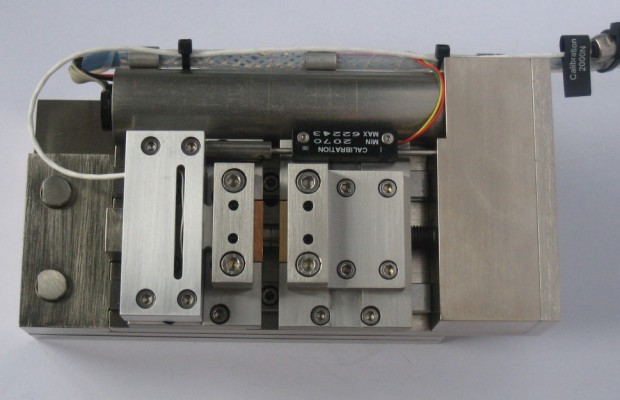

Model 110 Automatic Twin-Jet Electropolisher

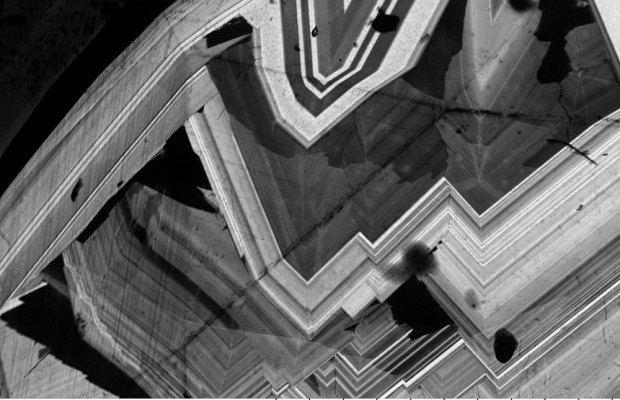

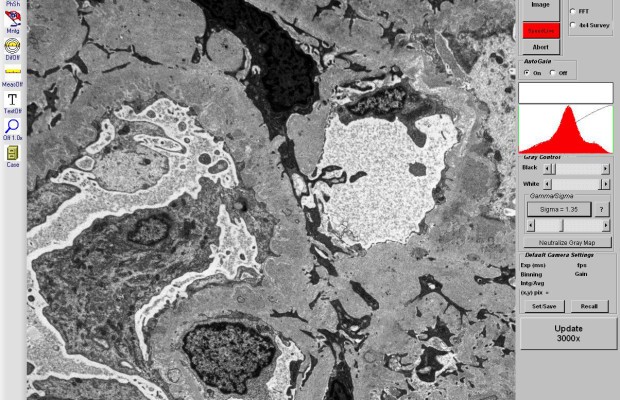

Conventional specimen preparation

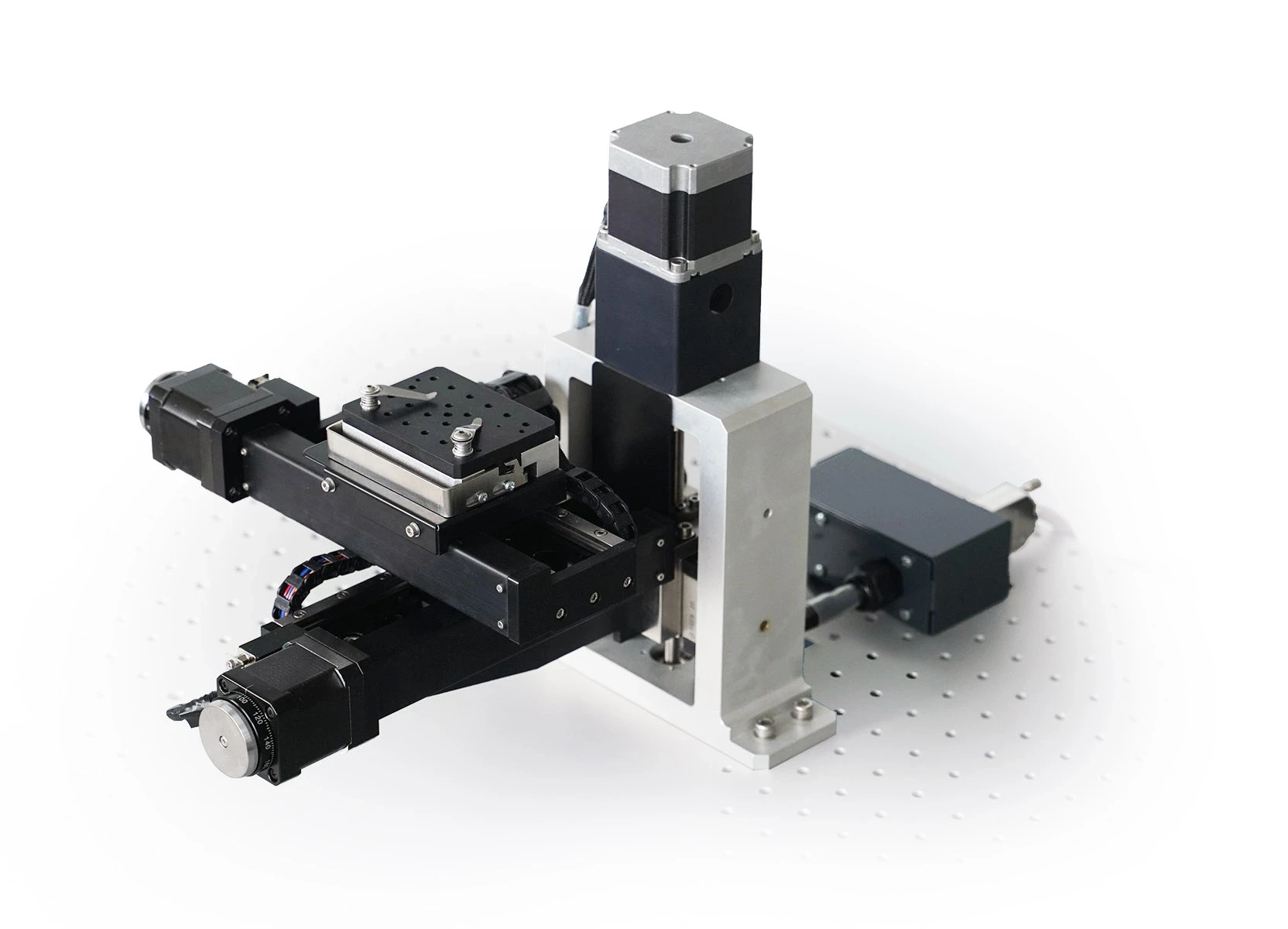

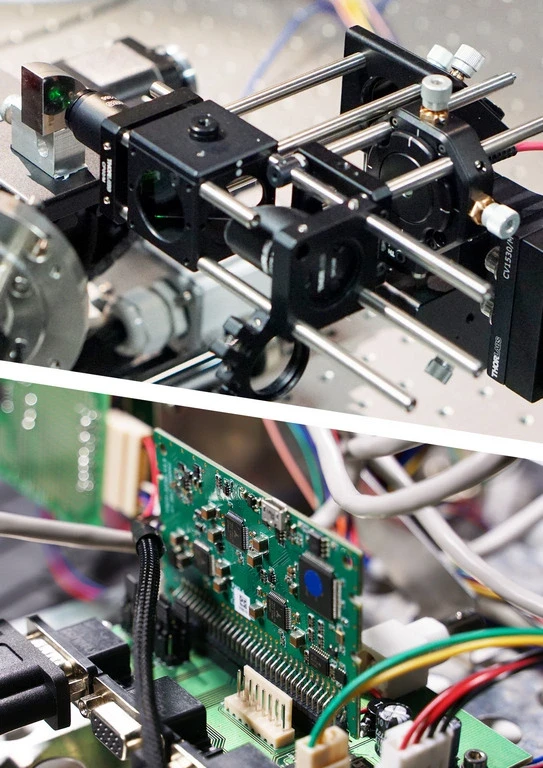

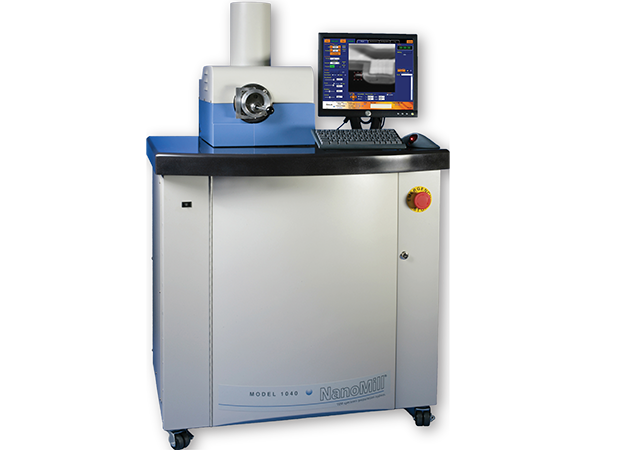

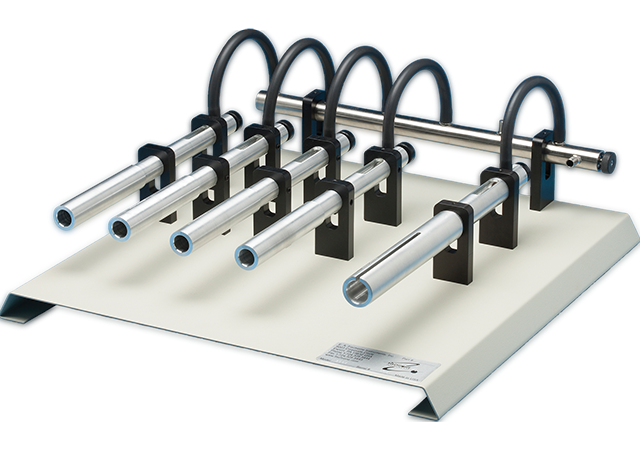

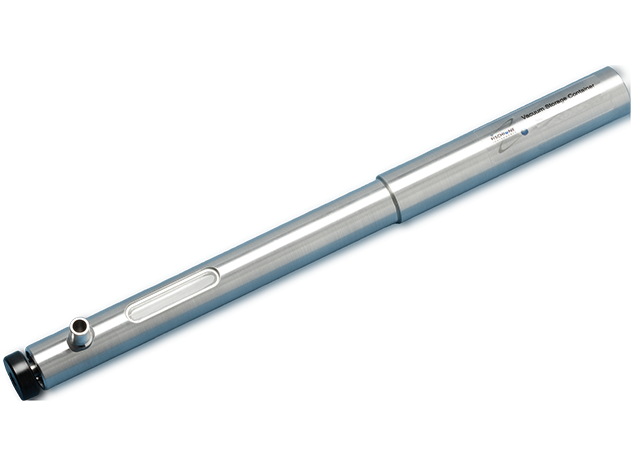

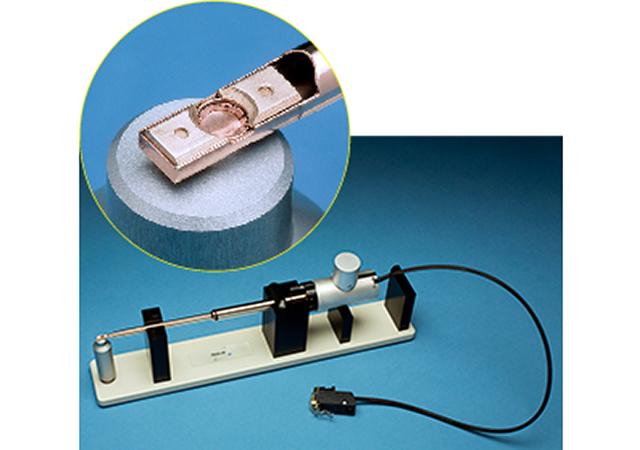

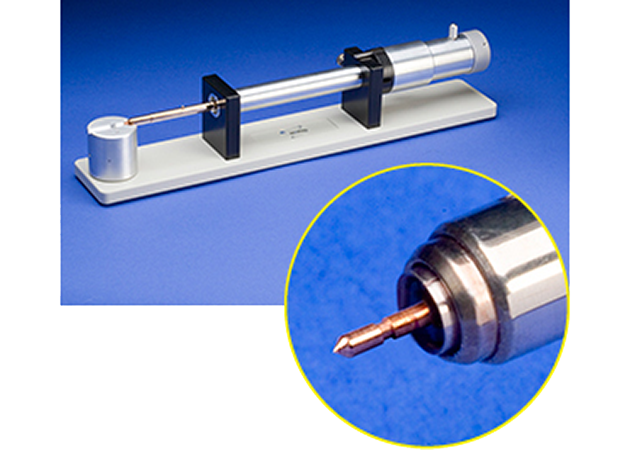

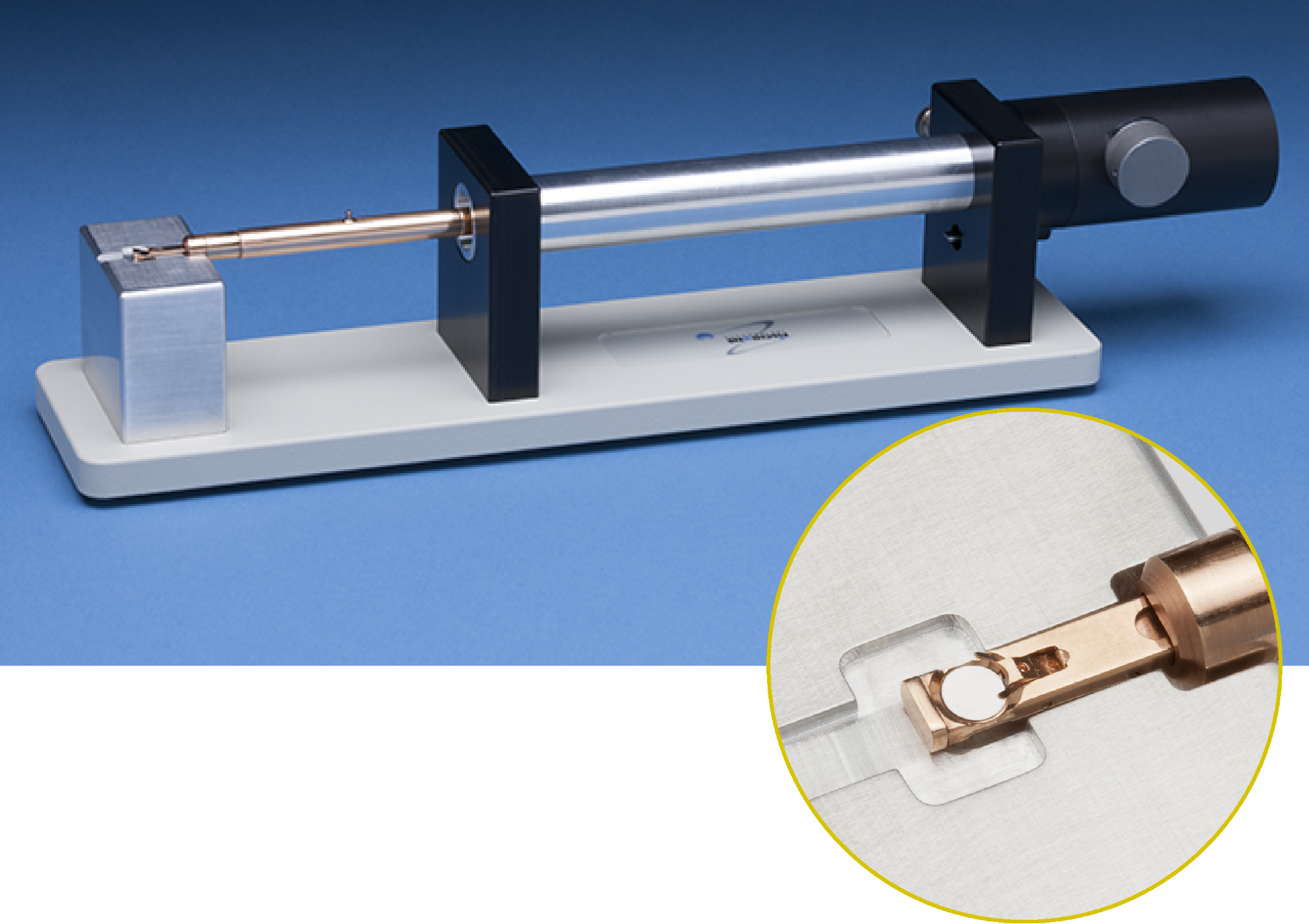

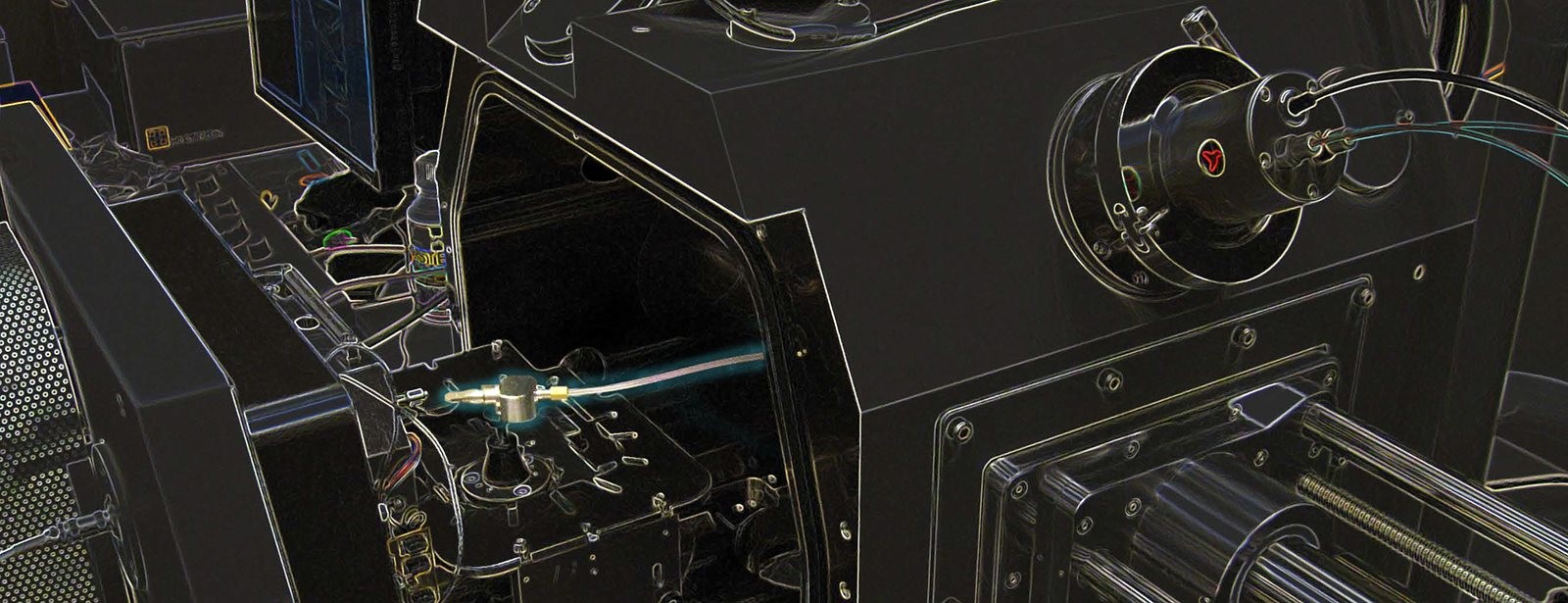

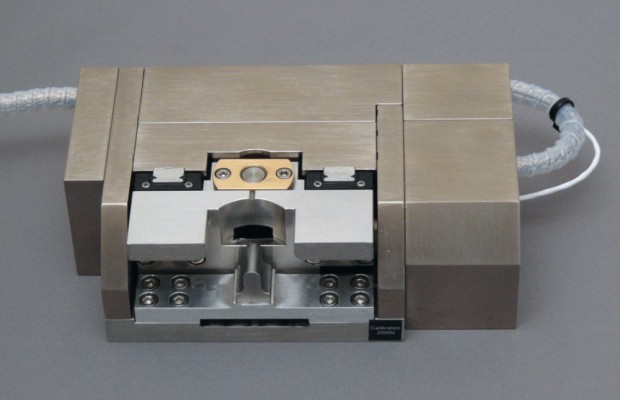

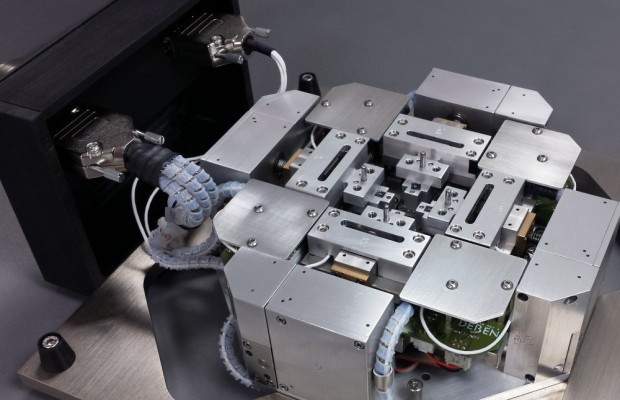

The Automatic Twin-Jet Electropolisher is used for the electrolytic thinning of TEM specimens. The twin-jet technique simultaneously polishes both sides of the specimen, creating electron transparency within a few minutes. Electrolyte flow and polishing voltage are controlled by either the Model 120 Automatic Power Control or the Model 140 Digital Power Control. Use the Model 220 Low Temp Container for applications at cryogenic temperatures.

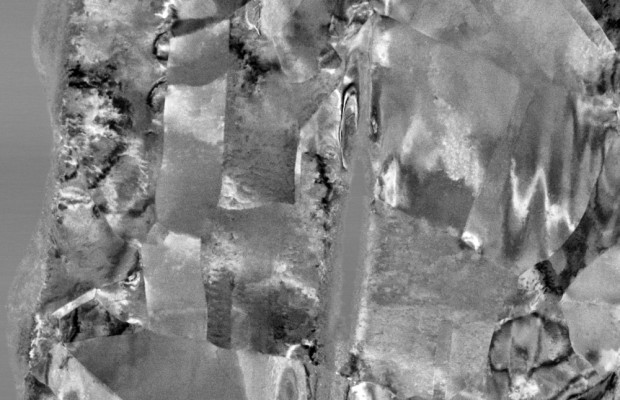

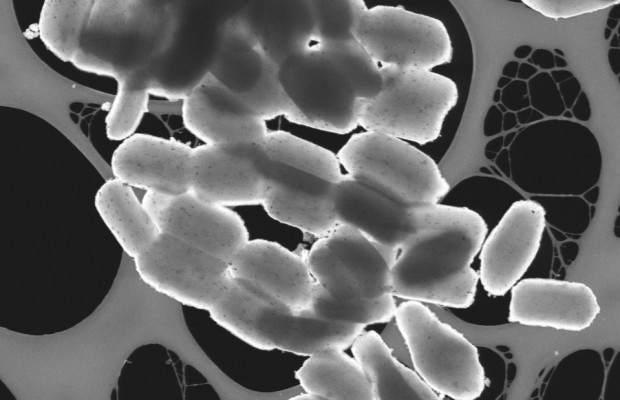

High-quality thin foils for TEM

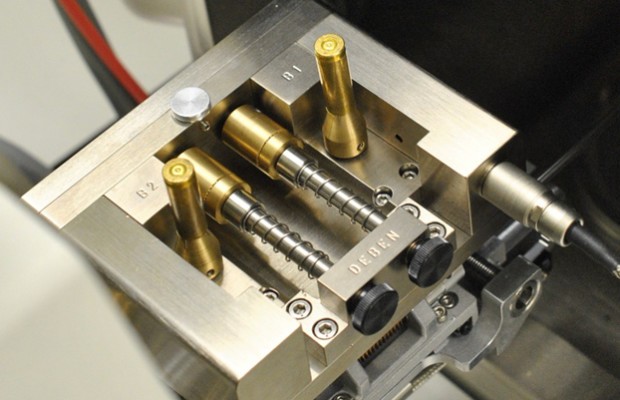

Electrolytic thinning of conductive materials is an effective method of quickly producing specimens for transmission electron microscopy (TEM) without any induced artifacts. In the Model 110 Twin-Jet Electropolisher, twin jets simultaneously polish both sides of the sample, creating electron transparent specimens within a few minutes. The electropolisher features easily adjustable electrolyte flow, polishing voltage, termination detection sensitivity, and jet and specimen holder positions.

Integrated operation

The electropolisher consists of the electrolyte pump and motor, jet assemblies, specimen holder, fiber optic assemblies (including the light source and photocell detector), and a box that holds a glass dish for the electrolyte.

Diğer Ürünler

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-