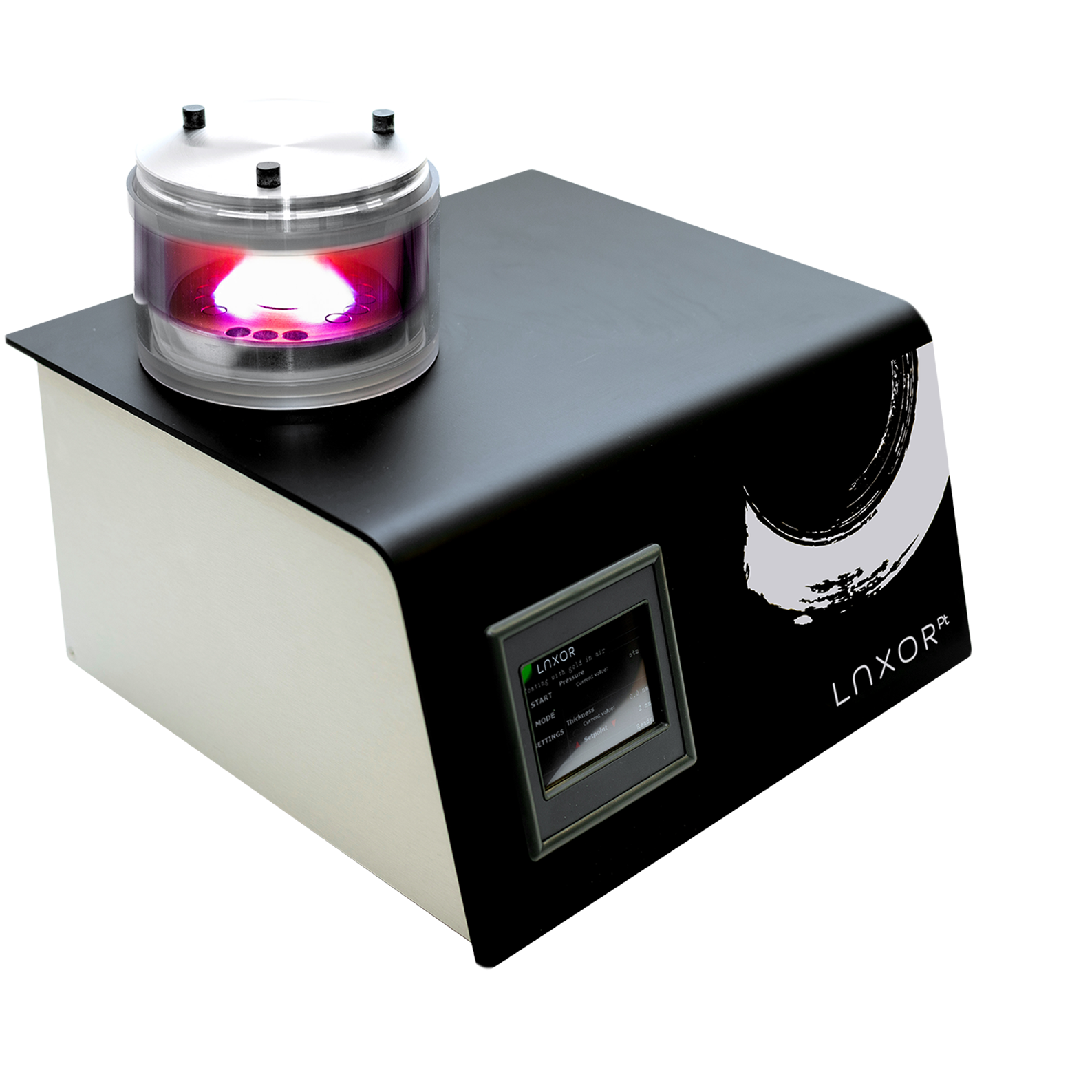

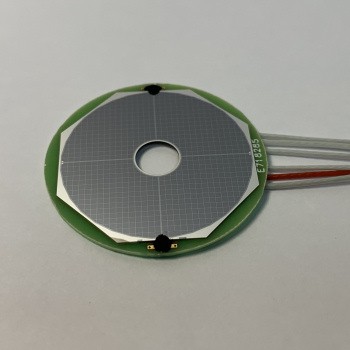

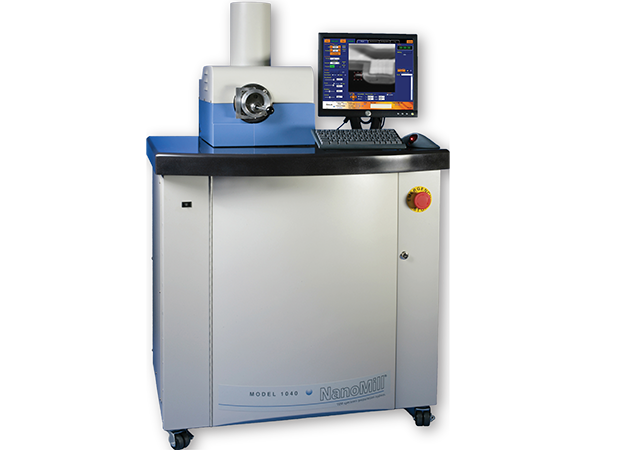

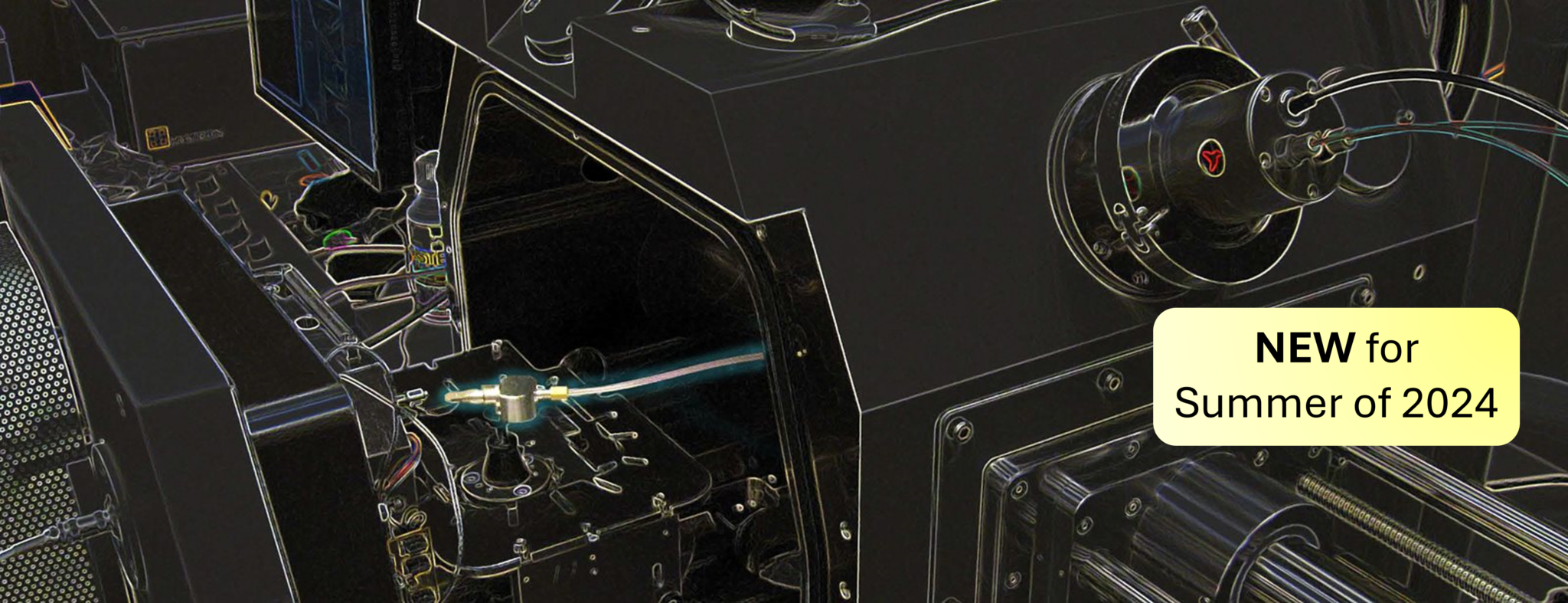

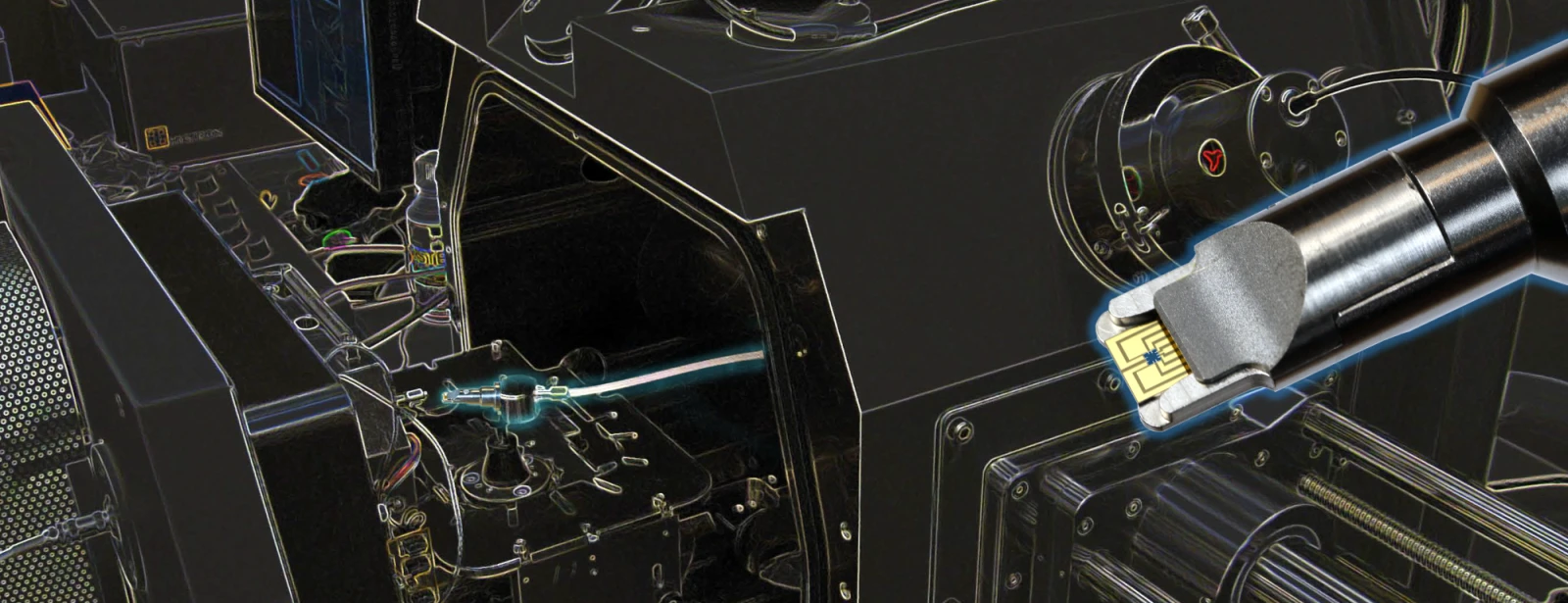

Model 1064

ChipMill

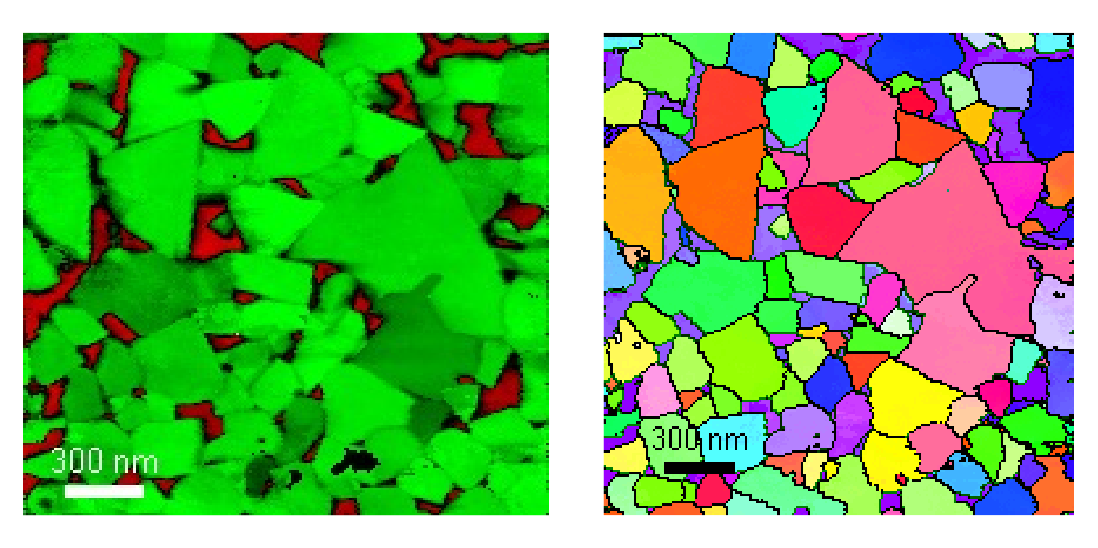

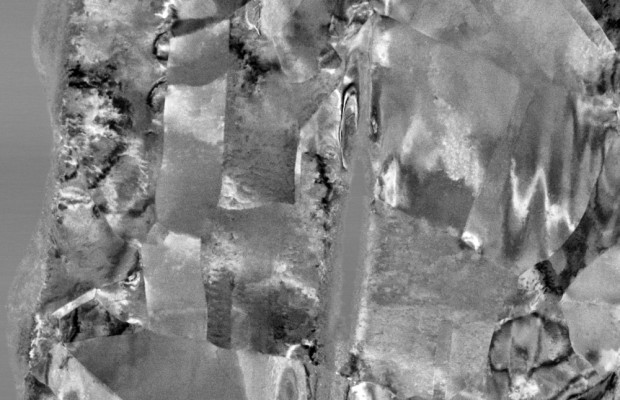

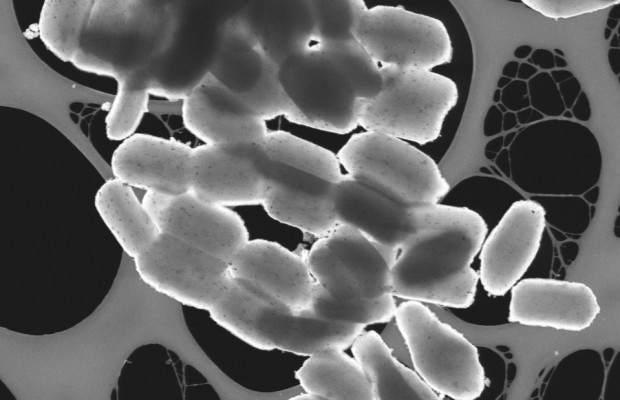

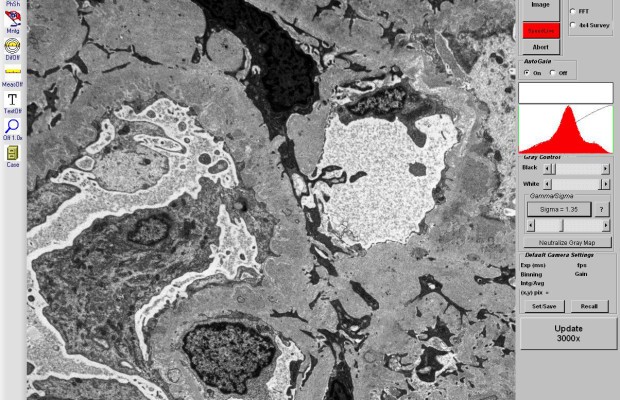

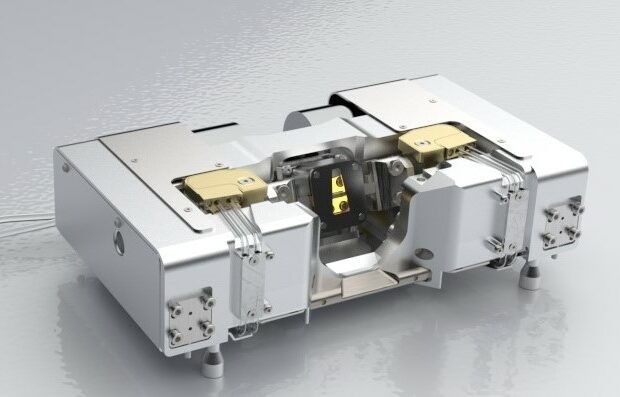

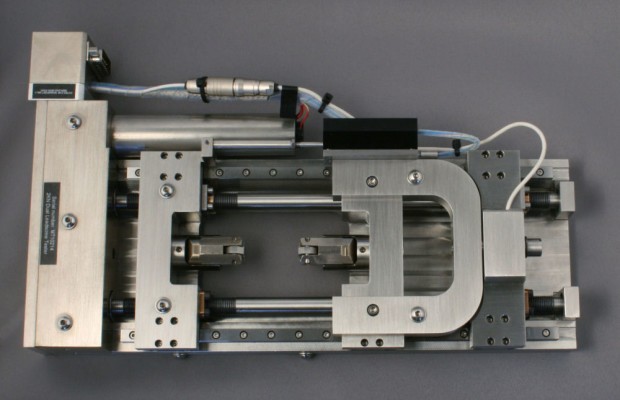

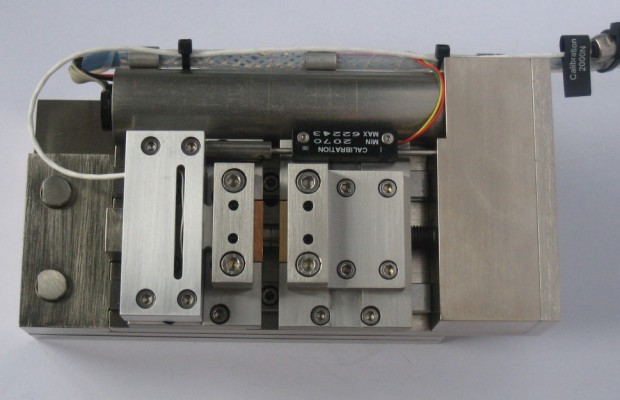

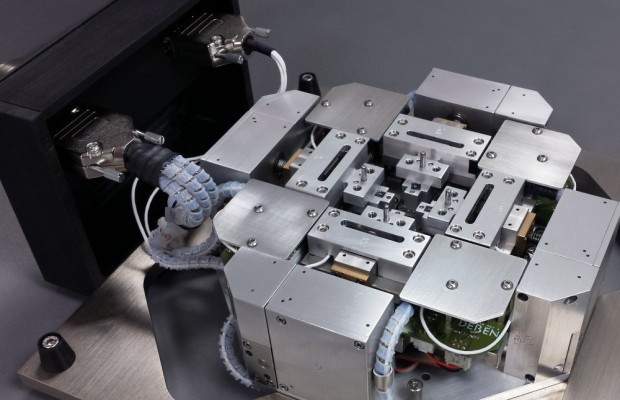

A fully integrated solution for millimeter-scale delayering of both logic and memory semiconductor devices. The ChipMill integrates signals from multiple detectors via an artificial intelligence feedback control algorithm to adjust milling parameters in real time. The result is the precise removal of device layers and a highly planar surface.

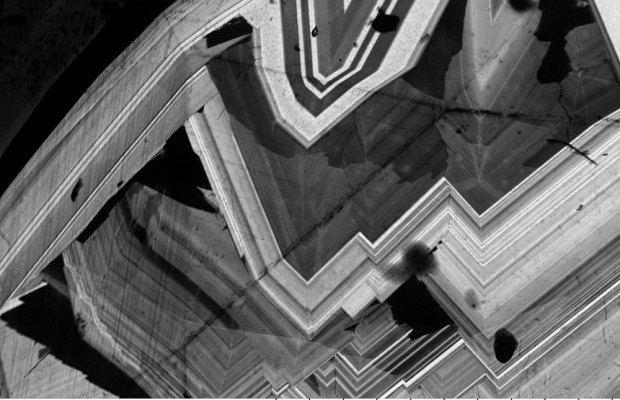

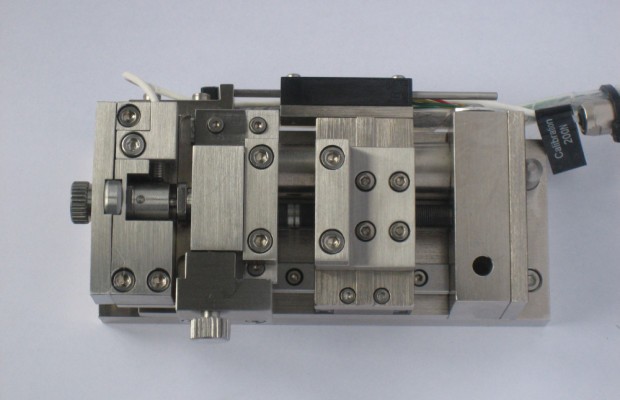

The Model 1064 ChipMill is a fully integrated solution for large-scale delayering – up to a 10 x 10 mm milling area – of both memory and logic semiconductor devices. Compared to all other methods, the ChipMill produces the flattest surface over the largest area. The ChipMill’s artificial intelligence automatically adjusts milling parameters to yield nanometer flatness within the prepared area.

The ChipMill reduces time and costs associated with research and development, manufacturing, quality assurance, and failure analysis by yielding unsurpassed results. As the demand for semiconductor devices grows, device sizes decrease, and architecture becomes more complex, the ability to perform controlled delayering during all phases of the product life cycle is essential.

Nanometer flatness of the prepared area

Milling area up to 10 x 10 mm

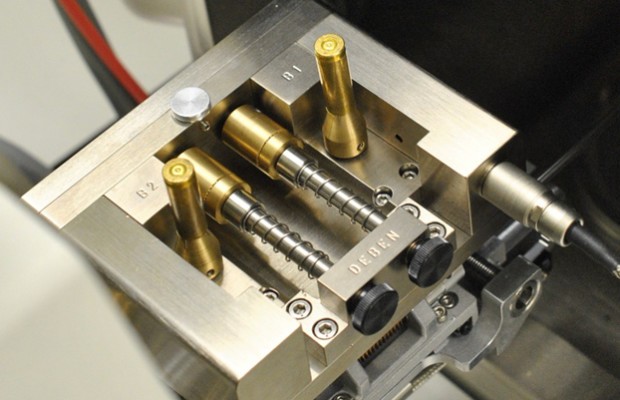

Automated sample height detection

User-friendly interface for the setup of milling parameters and display of images and analytical data

On-device touchscreen for managing sample insertion and removal

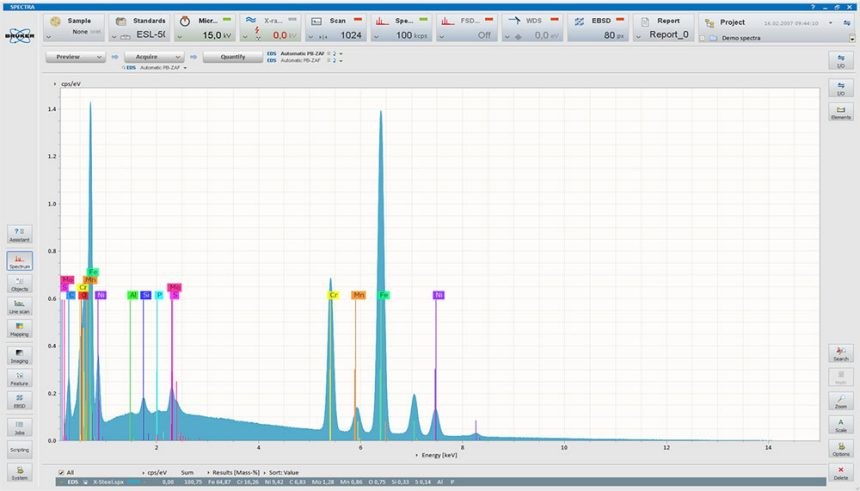

End-pointing by time, chip structure, or chemical composition

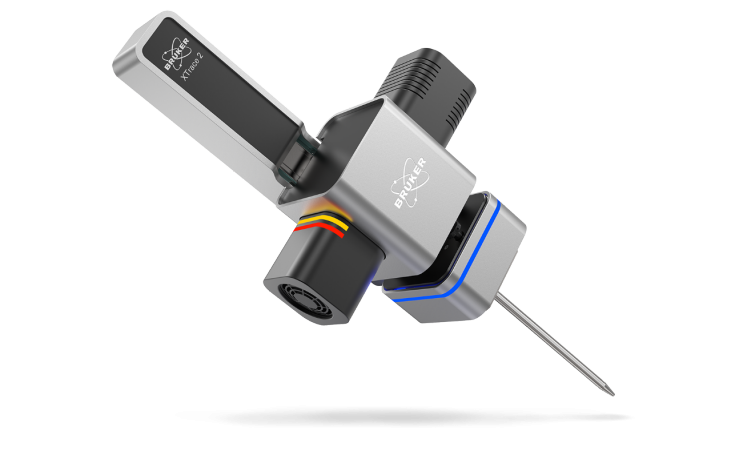

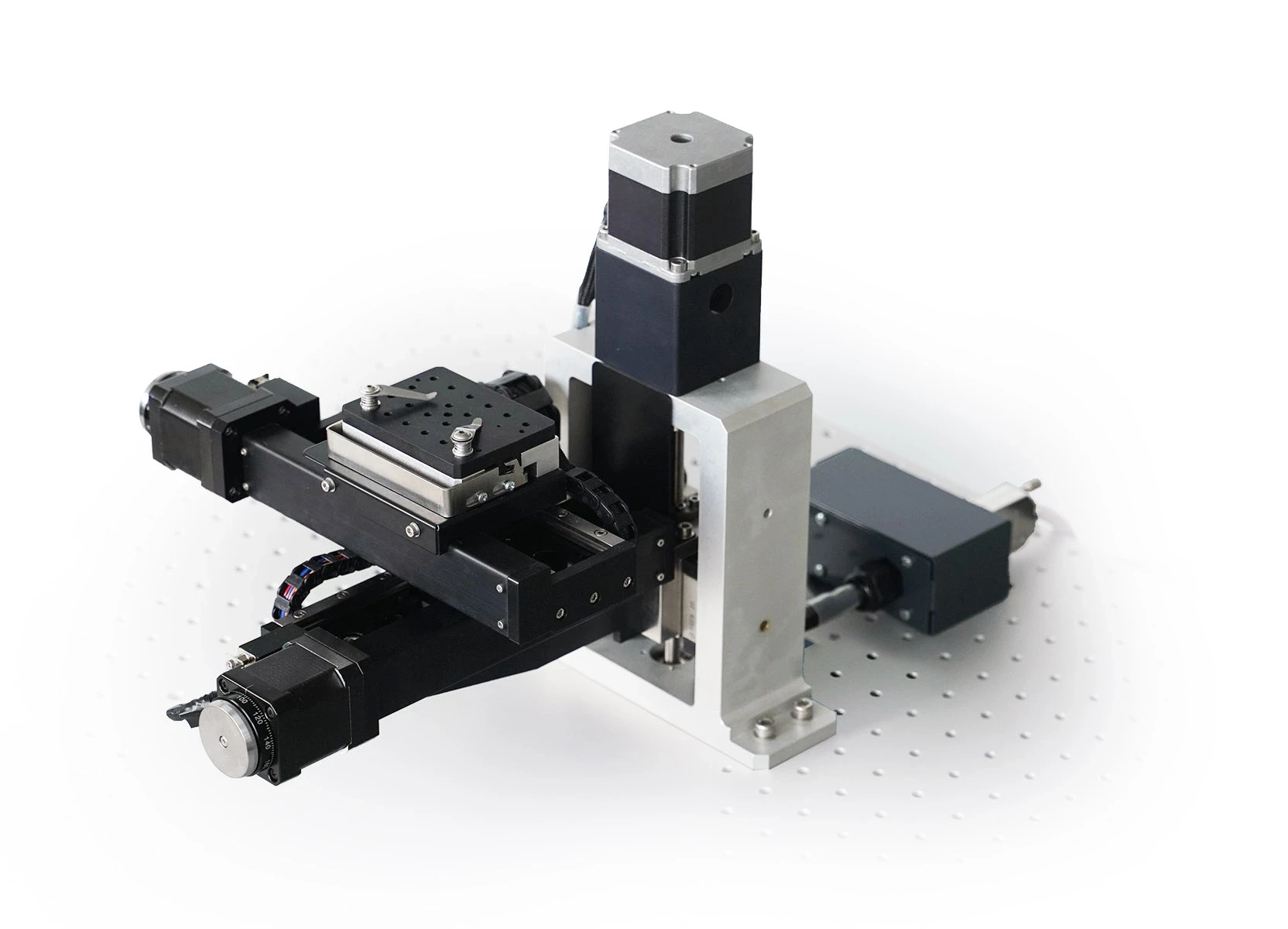

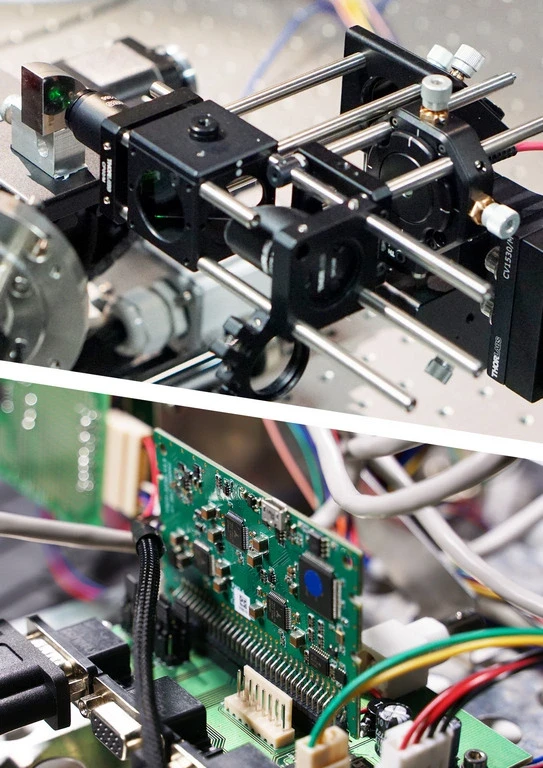

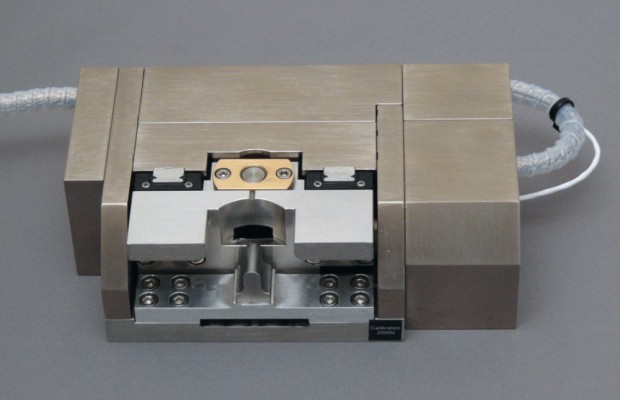

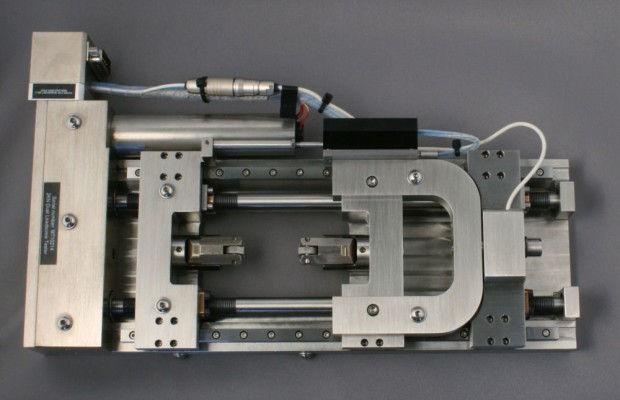

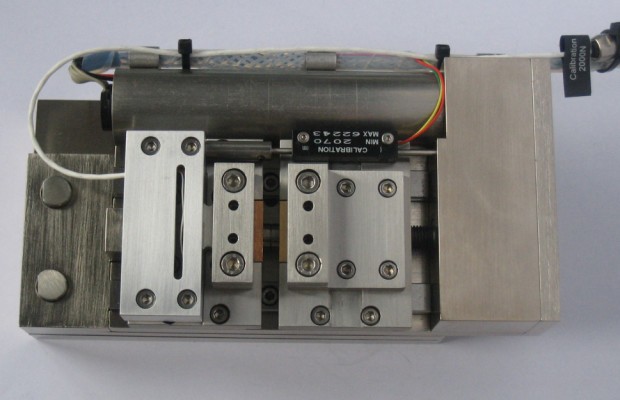

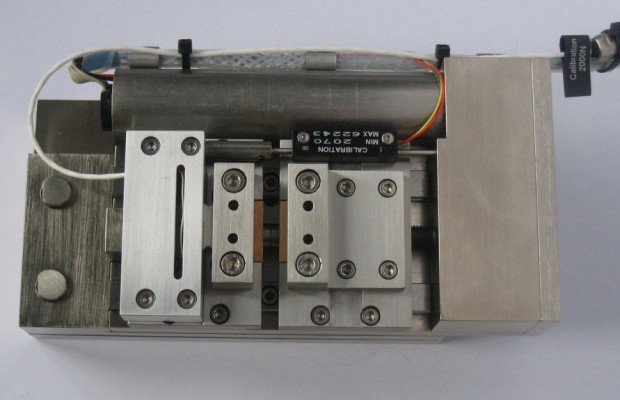

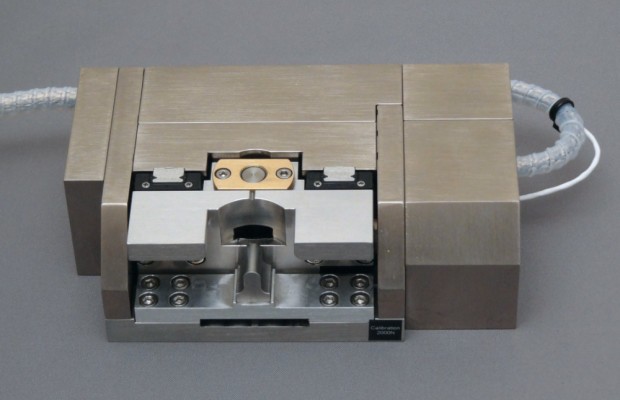

Components:

Ion source

Optical camera

Electron beam column

Secondary electron detector (SED)

Backscattered electron (BSE) detector

Energy dispersive X-ray spectrometer (EDS)

Secondary ion mass spectrometer (SIMS)

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-